Special Feature on the Americas

Initiatives for a V-Shaped Recovery in North America

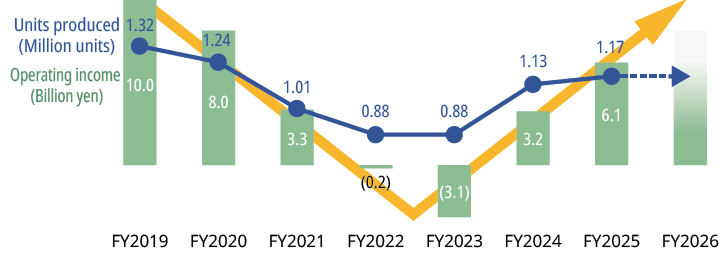

The Americas region is a vital strategic base for the Group, accounting for approximately 50% of total sales. Amid mounting pressure on profitability due to recent changes in the business environment, TS TECH has positioned a “V-shaped recovery in North America” as one of the key strategies in its 15th Medium-Term Management Plan and is actively pursuing initiatives to achieve this goal.

In this feature, we speak with local employees in the Americas about the current situation and their efforts toward realizing this recovery.

With over 30 years of experience and a proven track record in the industry, Paul now serves as Executive Vice President, where he is driving innovative approaches to support business growth.

With a background in product development, Richard now leads the corporate administration division, where he is driving initiatives to support a V-shaped recovery in North America, particularly in nonproduction functions.

How are the changes in the automotive industry perceived in the Americas?

Paul: The automotive industry in the Americas is currently being significantly affected by external influences, including shifts in government policy and the diversification of consumer preferences. In recent years, the transition to electric vehicles (EVs) has accelerated, prompting the industry to intensify its efforts in this area. At the same time, however, policy reversals—such as the withdrawal of EV mandates and the loosening of emissions regulations—have led to signs of a resurgence in gasoline-powered vehicles. These developments reflect the rapid and unpredictable changes occurring in the business environment, with ripple effects spreading throughout the supply chain. In this increasingly uncertain landscape, it is more important than ever to detect early signs of change and respond with agility and speed.

What is the current status of the V-shaped recovery in North America initiative?

Paul: A V-shaped recovery in North America is one of the key pillars of our regional strategy under the 15th Medium-Term Management Plan. Although this goal remains central, customer production plans have continued to fluctuate due to a combination of factors, including a sharp decline in production volumes during the COVID-19 pandemic and ongoing semiconductor shortages.

In such an uncertain environment, flexibility in responding to changing customer needs is essential. However, prolonged volatility may lead to employee turnover and, as a result, a potential increase in internal costs.

In response to the urgent need to improve profitability, we have further accelerated our ongoing initiatives toward high-efficiency production. By actively introducing new automation equipment—from assembly to shipping—we are improving production efficiency and driving cost reductions.

Richard: At the same time, improving employee retention has become a key priority. Recent changes in the external environment have brought about significant shifts in employees’ work styles and values. In particular, since the COVID-19 pandemic, there has been a growing emphasis on work-life balance and personal time. As a result, overtime and weekend work are increasingly linked to higher turnover rates.

In light of these circumstances, we have been steadily working to simplify and streamline business processes—not only in the production division but also in indirect departments such as human resources, accounting, and others— as part of our commitment to respecting work-life balance and fostering a workplace where employees feel safe and comfortable. Precisely because we are operating in such a challenging business environment, we remain deeply grateful to our employees who continue to work with us, and we are committed to improving workplace conditions and boosting motivation.

What is your vision for the future of TS TECH in the Americas?

Richard: Our goal is to further enhance operational efficiency by promoting the use of AI and digital transformation. Through rapid, data-driven decision-making, we aim to remain resilient and continue taking on challenges without giving up, even in the face of adversity.

Paul: The most important factor in future business operations will be the ability to flexibly adapt to change as needed. As we continue our transformation toward a more resilient corporate structure, we remain committed to cherishing the colleagues who have stood with us through past challenges.

Inside the Front Lines of Profitability Recovery in North America:

Challenges Taken On by the People Leading the V-Shaped Recovery

Among all segments of our Group, the Americas region faced one of the most challenging business environments. Yet, it was able to achieve a swift V-shaped recovery in North America—thanks to the dedication of employees across various functions who worked tirelessly toward this goal. In this feature, we speak with local team members about the challenges they encountered and how they overcame them.

What specific initiatives have you undertaken across different areas to drive the V-shaped recovery in North America?

Steve: Under the TS TECH Group’s 15th Medium-Term Management Plan, one of our key strategic priorities continues to be achieving a V-shaped recovery in North America. To realize this, our Americas operations have focused on three core initiatives.

First, we are enhancing production efficiency while maintaining high product quality. By integrating these elements at a high level, we have built a system that ensures stable supply and minimizes production losses.

Second, we are driving profitability through VA/VE (Value Analysis/Value Engineering) activities. Cross-functional teams from development, sales, and purchasing have collaborated to reassess component sourcing and strengthen partnerships with suppliers to improve cost efficiency.

Third, we are expanding our customer base and expanding our new commercial rights. By showcasing our products at automotive technology exhibitions, we have created opportunities for direct engagement with potential customers, leading to new business development.

Joe: While the development department focused on designing products that are easy to manufacture, the sales and purchasing divisions concentrated on cost reduction to enhance product competitiveness. As part of this initiative, we reviewed our supply chain and reidentified competitive suppliers that meet our internal standards. Taking into account the geographical relationship between our plants and suppliers, we prioritized nearby suppliers to improve logistics efficiency and reduce transportation costs. We also visited Group companies and suppliers across the Americas to closely examine procurement routes and design specifications, and other related aspects of individual components, identifying areas for improvement and implementing changes step by step.

Jamie: In the area of production, we have worked to enhance efficiency through automation, while also striving to boost engagement among production employees. Although we continue to expand the scope of automation, this does not mean that all manual processes have been eliminated. We remain mindful that manufacturing is only possible thanks to the dedication of our employees on the production line. By properly recognizing their daily efforts and expressing our appreciation, we aim to foster stronger engagement. This approach helps reduce employee turnover, thereby minimizing the training time and personnel costs associated with workforce changes.

Furthermore, by minimizing disposal costs and production line downtime caused by defective products, we reduce related production losses and overtime, achieving both greater efficiency and improved work-life balance. We believe that creating a comfortable work environment—while embracing the diverse cultures and values of our employees— is based on our corporate philosophy of being “A company dedicated to realizing people’s potential.”

Tsuge: In terms of our production facilities, we have actively promoted the development of a highly efficient production system through automation. Achieving such efficiency requires improvements on both the software and hardware fronts. On the software side, as previously noted, we have worked to improve the working environment, while on the hardware side, we have focused primarily on implementing automation technologies.

Since the beginning of the 15th Medium-Term Management Plan, we have been facing a persistent labor shortage, and a rapid improvement in this situation is unlikely in the near future. To address this challenge, we must continue advancing automation initiatives. Automation not only improves production efficiency but also contributes to a more comfortable working environment by reducing the need for manual handling of heavy components.

Currently, TS TECH USA CORPORATION has the most advanced automation technologies in the Americas for transporting components and finished products within the plant. We intend to actively deploy these technologies across other sites in the future.

What was a particularly difficult aspect of achieving a V-shaped recovery?

Steve: In development, we promoted VA/VE initiatives to achieve both cost reduction and ease of manufacturing in our designs. Naturally, customers expect high-quality products at competitive prices. To meet these expectations, we must challenge conventional design approaches and pursue innovative product development without being constrained by past practices.

In addition, the rapidly changing market environment has significantly accelerated the pace of product development compared to just a few years ago. Designing highquality products within shorter time frames is no easy task. To remain competitive, companies must be able to adapt flexibly—not only in their development methodologies but also in how they allocate personnel and structure their organizations.

Jamie: In production, our biggest challenge was staffing. Customer production schedules were highly volatile, making it difficult for any part of the supply chain to plan accurately. Under these conditions, flexible production became even more critical, and we frequently had to operate on scheduled days off.

In particular, Saturday shifts—which had previously occurred only once a month before COVID-19—became almost weekly for a time. This led to a vicious cycle of rising workloads and continued employee attrition.

Joe: While the impact of COVID-19 played a role in the situation, changes in government economic policies and other external factors have also had a significant effect. When policies shift, customer strategies often follow suit, requiring a coordinated response across the entire supply chain.

Our main customer had initially planned to focus on EV production in the Americas, but in response to changing external conditions, it has revised its strategy to continue producing gasoline-powered vehicles for the time being. We were in the midst of preparing for this transition, and as part of the supply chain, we must build a resilient team capable of responding flexibly to such sudden changes.

Jamie: These challenges could not be resolved by our efforts alone, but we remained committed to finding solutions. We focused on improving our production lines—including automation and other process enhancements—and worked to build systems such as inventory management that can flexibly respond to production fluctuations.

As a result, weekend and holiday work decreased, leading to a more positive atmosphere within the company and contributing to a gradual decline in employee turnover across departments.

Tsuge: Through a range of initiatives—from large-scale investments to improvements on the production floor—we are seeing a positive trend in profitability. A strong directive from management emphasized the need to prepare for a shift in market conditions in which EVs and gasoline-powerel vehicles would grow in parallel.

In line with this directive, we proactively prepared our operations, and as a result, we have made progress in building flexible production lines capable of efficiently manufacturing a wide range of models to meet diverse customer needs. We believe these production lines will become a key driver of our future growth.

What initiatives are planned for the future?

Steve:

To navigate these turbulent times, companies must maintain a high level of competitiveness. If we fail to adapt to the changes ahead, we risk falling behind our competitors. Embracing change and continuing to take on challenges with a flexible mindset will be key to acquiring new commercial rights and gaining new customers.

Jamie:

To drive business transformation, we must adopt new perspectives and break free from conventional thinking. By actively leveraging AI and other technologies, software, and systems, we believe we can achieve further improvements not only in production but also across administrative functions such as human resources and finance.

Tsuge:

Under the 15th Medium-Term Management Plan, we actively promoted automation across our operations, and we intend to further accelerate the deployment of automation technologies in the next plan. To support continued automation and the evolution of our production lines, we are working closely with the Engineering Center in Japan to streamline equipment testing and other preparatory steps, enabling the early launch of new automated systems.

Joe: Teamwork is essential for manufacturing that meets the expectations of all stakeholders. At the TS TECH Group, we foster strong collaboration between Japan and North America, within each site in the Americas, and at times with other regions. This is undeniably one of our core strengths.

In my area, we are further enhancing organizational resilience and flexibility by strengthening collaboration with suppliers. Drawing confidence from the teamwork that has enabled us to overcome numerous challenges, we will continue to move forward as one unified team— advancing our V-shaped recovery and striving for sustainable growth beyond it.

Established: May 1995

Business areas: General management of Americas region

Research and development

The Americas Head Office

Established: December 1994

Business areas: Manufacturing of seats and seat frames for four-wheeled vehicles

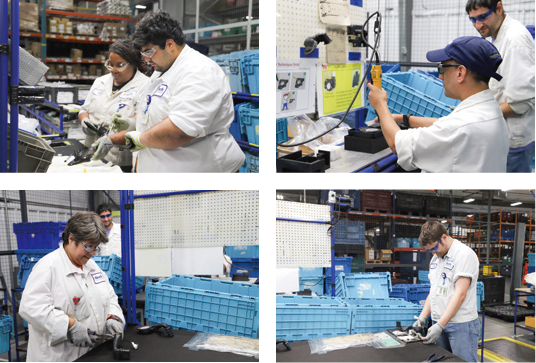

Sustainability line at TS TECH USA CORPORATION plant

As part of our commitment to sustainability, we have established a dedicated production line within the plant to provide a safe and supportive environment for employees with disabilities. By performing tasks aligned with their individual strengths, these team members contribute meaningfully to our manufacturing operations.

This initiative exemplifies how one of our Group’s core corporate philosophies.being “A company dedicated to realizing people’s potential”.is deeply embedded in our daily operations.

Automation and Efficiency in Production Processes in the Americas

As part of our efforts to achieve a V-shaped recovery in North America, we are developing a highly efficient production system for each production site. One specific example is the adoption of automation equipment by TS TECH USA CORPORATION, our primary production site in the United States.

Autonomous Mobile Robot (AMR)

In fiscal 2023, we introduced AMRs into the factory to perform autonomous parts conveyance between production processes. In the past, we used magnetically guided automated guided vehicles (AGVs) and embedded magnets in the floor to mark the conveyance routes. However, this necessitated construction when changing or building new routes, and caused issues with annual repair costs and the time required for bringing routes on line. The new AMRs we introduced use a built-in camera to automatically grasp the layout of the factory and move autonomously. This has eliminated the need for construction when changing the factory layout, and allowed for more flexible operation. As a result, we were able to reduce the labor required for transport by 25% under our 15th Medium-Term Management Plan and curtail annual repair costs to 1/6th of what they were previously. Moreover, AMRs can move 40% faster than AGVs, helping to make internal factory logistics significantly more efficient.

Automated Storage and Retrieval System (ASRS)

When manufacturing products, the model and specifications (such as equipment and color) must be delivered in alignment with the customer’s production schedule and delivery format. Previously, we assembled front and rear seats on separate production lines and stored them together on a single pallet in an automated storage and retrieval system (ASRS), which allowed for non-manual storage and retrieval. These were then shipped at the appropriate time according to the customer’s production sequence.

However, under this method, if one production line was halted for quality inspection, the other line also had to stop, resulting in idle time. Prolonged production instability led to increased overtime, which significantly impacted operational efficiency. To address this, we are currently expanding the ASRS and reconfiguring the factory layout to make each production line independent. We have established a system in which completed front and rear seats are stored separately, and retrieved individually from the ASRS before shipment to be placed on pallets. This enables more flexible production on each line and is expected to reduce production losses. In addition, we plan for the stabilization of production to help reduce our employee turnover rate by decreasing overtime hours and holiday work.