Environmental technologies

Product development to minimize environmental impact

TS TECH is developing lighter products to improve vehicle fuel consumption while incorporating materials that generate lower environmental impact.

To develop lighter models while maintaining safety and comfort, we seek constantly to reduce weight from previous models by reviewing the constituent parts of each product from the design stage and reducing numbers of parts based on advances in materials research and processing technologies.

We will continue striving to develop eco-friendly products as part of our mission to cut environmental impact.

Toward more eco-friendly vehicles

BEVs and hybrids, whose market shares have grown in recent years, require not just lighter parts—they tend to have more confined interior spaces than gasoline-powered vehicles due to unique body lines, battery layouts, and other factors.

TS TECH is developing advanced seats to meet these needs through R&D on seat forms that maximize interior space, enable more flexible body installation designs, and improve comfort.

Weight reduction efforts

We understand that reducing the weight of our products is one of the most effective ways in which we can reduce our impact on the environment. For example, our seat frames account for a large portion of the weight of our products, so we strive to apply a variety of weight-reducing technologies wherever possible, while further improving safety and comfort in line with evolving needs. The seat frame installed in the 2020 Honda Fit is about 28% lighter than our previous core frame. We accomplished this by using more ultra-high tensile strength steel and thin-plate welding technology. It is now being used in many automobile models worldwide.

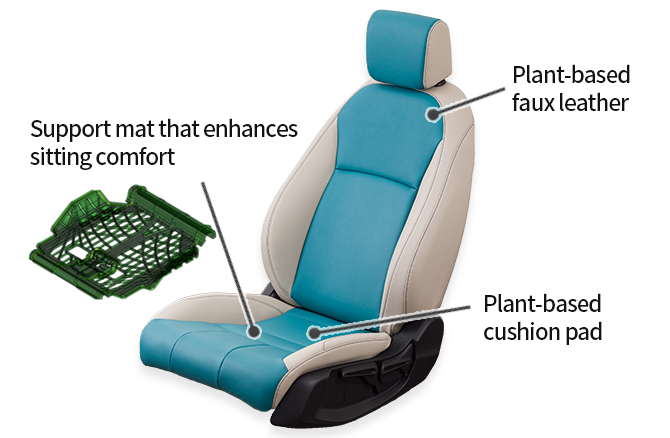

Sustainable seats

We're developing products that use plant-based and recycled materials.

Despite concerns that switching materials may reduce seat comfort, we have developed technologies that ensure comfort via structural design of the whole seat by incorporating our proprietary support mats and other measures.

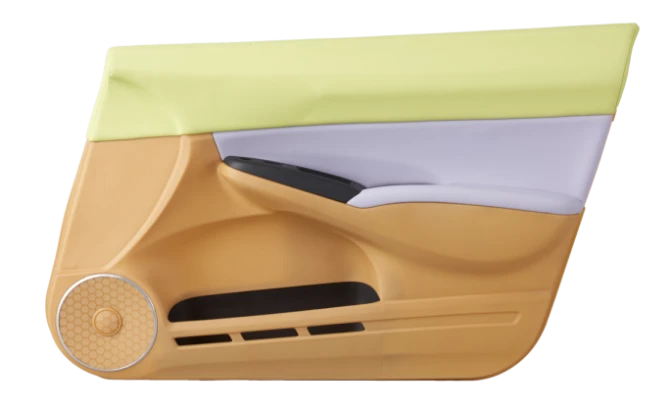

Cellulose nanofiber (CNF) door trim

We're also focusing on technologies that use cellulose nanofiber (CNF) and other plant-based biomass materials to reduce CO2 emissions generated by the products.

We reduced product CO2 emissions by 60% through the use of plant-based biomass materials (resins and surface materials) in place of traditional door trims made of petroleum products, and plan to apply this technology to mass-produced products.