Pursuing safety

Continuing to pursue passenger safety through state-of-the-art equipment and advanced technologies

TS TECH develops safety technologies to protect the passengers in its seats.

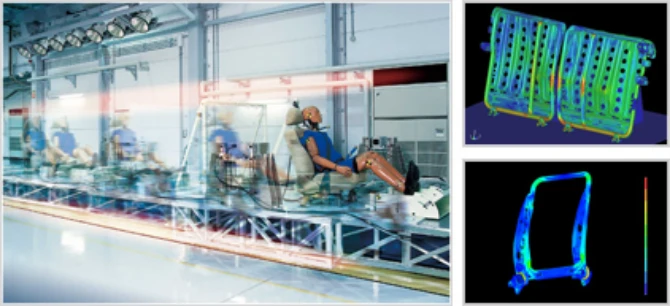

Our Safety Technical Center in Tochigi Prefecture, Japan and TS TECH AMERICAS use industry-leading, state-of-the-art equipment in daily R&D with the aim of ensuring passenger safety.

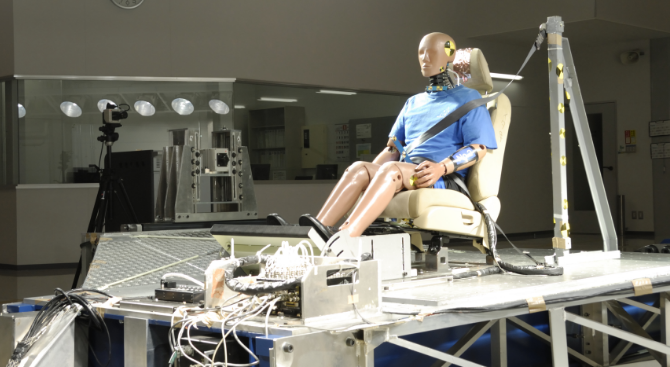

Verifying seat safety through testing from various angles

The Safety Technical Center employs various testing equipment, including two dynamic testers, and CAE analysis technologies in R&D conducted to verify and further improve product safety from various angles.

We deliver to the world safe seats that have passed various tests, including front impact dynamic testing to measure product durability and passenger injury figures in front collisions, seatbelt anchorage testing to measure seatbelt strength, trunk-barrier dynamic testing to test product strength when baggage in the trunk impacts rear seats in a collision, and airbag deployment testing to verify airbag performance and damage.

Neck shock mitigation seat

This structure developed by TS TECH to mitigation impact on the neck from a rear collision has earned high assessments from global assessment agencies, including Euro NCAP*1 and JNCAP*2.

- Euro NCAP: European New Car Assessment Programme

- JNCAP: Japan New Car Assessment Program

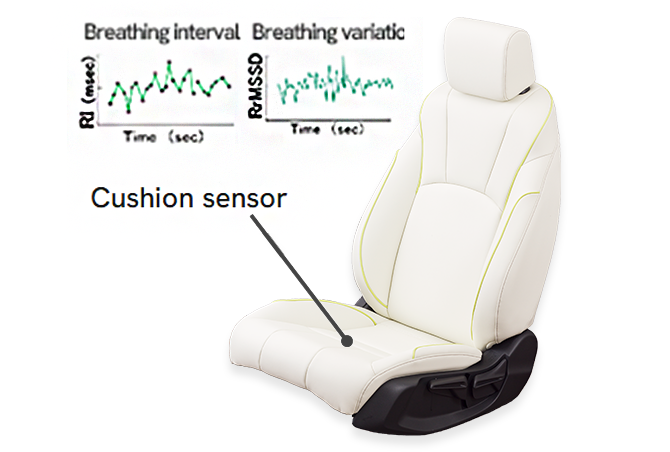

Biosensing seat

Sensors installed in the seat detect pressure on the seat surface and biometric information such as breathing. Based on the sensor readings, our proprietary AI provides estimates of passenger condition (such as fatigue and sleepiness) and supports safe driving through means such as encouraging the driver to take a rest as needed.

Ultimately, through linkage with ADAS this is expected to contribute as accident-prevention technology through means such as stopping the vehicle if there is a problem with the driver.