Development of Car Parts That Use Environmentally Friendly Materials

Development of Car Parts That Use Environmentally Friendly Materials

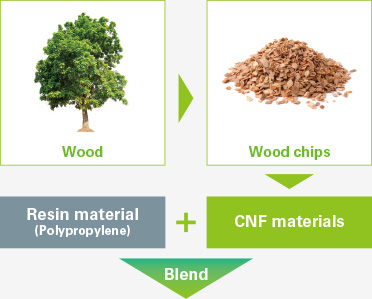

TS TECH is conducting research into how cellulose nanofiber (CNF), a plant-derived material that has gained attention in the automobile field for its low environmental impact and its high functionality, can be used in interior components.

Environmentally Friendly Manufacturing Will Shape the Future of the Automotive Industry

In order to contribute to the creation of a sustainable society as a company in the automotive industry, we must work to reduce our environmental impact by reducing product weight, which improves fuel consumption and cuts material use, and using environmentally friendly materials.

As part of these efforts, we participated in an evaluation of samples provided by the “Development of Technologies for Manufacturing Processes of Chemicals Derived from Inedible Plants”/“Development of Integrated Manufacturing Processes for High-Performance Ligno-CNF and Technologies for Their Commercial Application” project conducted by Japan’s New Energy and Industrial Technology Development Organization (NEDO)*1. We also successfully molded door trim using reinforced resin containing CNF and verified its performance.

CNF-reinforced resin is exceptionally stiff and can also be made very thin. While these qualities make it a way to reduce weight, it is also very fragile and breaks easily, so it can be difficult to mold. TS TECH used polypropylene mixed with a CNF with a mass percent*2 of 10%, which was provided as an evaluation sample. This polypropylene/CNF material was molded to a sheet thickness that was 1.5 mm, thinner than 2.0 mm door trim made with conventional materials, and its weight was 17% lighter.

What is cellulose nanofiber (CNF) ?

Cutting-edge biomass nanofiber material created by separating plant-derived cellulose into pieces of 3 to several 100 nm in diameter and several μm in length

Since CNF is derived from plants, it has five times the strength of steel, but one-fifth the weight, giving it impressive strength and lightness. It is also a renewable resource, and in Japan, which has few resources, it is attracting attention as a new material that utilizes forest resources. By using CNF to make automobile components, we can help to make parts even lighter, improve fuel consumption, and reduce the environmental load.

- The New Energy and Industrial Technology Development Organization (NEDO) is a national research and development organization that plays a key role in Japan’s economic and industrial policies by promoting development of technology to solve energy and global environmental problems as well as bolster industry’s technical strengths. NEDO aims to combine the technical and research strengths of industry, academia, and the public sector to solve social issues and create markets.

- Mass percent: The mass of the solute divided by the mass of the solution