Technology TOP interview

What technologies are sources of competitiveness for the TS TECH Group?

At the TS TECH Group, we aim to develop world-leading, advanced technologies with a focus on safety, the environment, and the creation of attractive products. Regarding safety-related technology, we are working with vehicle manufacturers to develop products that will meet the anticipated safety standards several years from now. To do this, we obtain information from relevant organizations in various countries, such as NHTSA1 and IIHS2 in North America, and the Ministry of Land, Infrastructure, Transport and Tourism in Japan. When it comes to safety, we have been an industry pioneer. We were the first in Japan to utilize a dynamic sled testing facility that faithfully reproduces the impact of a vehicle collision. By conducting tests that simulate a range of conditions, we have continued to pursue technology that protects the safety of passengers. Looking back at the history of our products and safety, there have been major advancements since the early 2000s. In 2005, we provided an Active Headrest3 to Honda Motor Co., Ltd., our main customer, to reduce the impact to the neck for vehicle occupants in the event of a collision, thereby improving safety. As a result of accelerating R&D concerning seat frame construction to improve safety performance, our products boast world’s top-class safety performance. Currently, all of the vehicle models equipped with our products have received the highest ratings for seat-related safety performance in vehicle assessment worldwide.

As a supplier to the automobile industry, we are required to develop technologies that help protect the environment. Our aim is to promote recycling-oriented manufacturing and help improve vehicle fuel efficiency, as part of efforts to help build a sustainable world. The Group has been investigating the use of sustainable plant-based materials that contain no fossil fuels to make seats. However, the use of such materials can pose challenges such as higher costs and a decrease in seat comfort. Therefore, we have been pursuing further R&D to see if we can solve the drawbacks of such materials by modifying the seat construction, which would allow us to adopt the new materials for practical use. Currently, automakers are also engaged in fullscale efforts to adopt sustainable materials. Therefore, by establishing technologies that can be applied to products before bringing them to market as quickly as possible, we want to help build a sustainable world while enhancing our technological competitiveness.

In the area of new technology for the creation of appealing products, the Group has continued to pursue “comfort” since its founding. Judgments about comfort and resistance to fatigue differ depending on the person. Therefore, we have accumulated unique expertise and technologies that allow us to quantify and evaluate occupant comfort judgments in order to support our manufacturing process. To create seats that properly support the human body with superior comfort, we have been conducting ergonomicsbased research using quantitative evaluation. With unique theoretical frameworks established based on this, we are working to bring even more comfortable seats to the market. Moreover, the pursuit of comfort in particular is multifaceted and deep, and over the course of time, this pursuit is subject to an infinite process of evolution. We believe that providing comfort also means making more effective use of the limited space inside the vehicle, increasing convenience, and making time spent in the vehicle more enjoyable. We have worked to improve comfort by creating our Functional Seat that enables a variety of interior arrangements. The third-row seats can be folded flat into the floor with a minimum number of operations, while the second-row seats have a mechanism that allows them to slide forward or backward as well as left or right with the operation of a single lever. This allows the vehicle users to enjoy a variety of seating arrangements. The various seat arrangement technologies that we have devised so far, including those that allow seats to be rotated, moved, and stowed as necessary, have often surprised and delighted our automaker clients. The foundation of the TS TECH Group’s competitiveness rests on the core technologies we have developed over the years to support safety, the environment, and the creation of appealing products.

- 1 National Highway Traffic Safety Administration (NHTSA): An agency in the U.S. Department of Transportation that ensures safety for vehicles and drivers

- 2 Insurance Institute for Highway Safety (IIHS): A u.s.-based non-profit organization established by automobile insurance companies to evaluate automobile safety

- 3 Active Headrest: In the event of a rear-end collision, the headrest automatically moves forward to greatly minimize neck injuries. It is activated by the force applied to the seat by the occupant’s body being pushed backward.

Can you tell us about the results of the 14th Medium-Term Management Plan?

Among the seven priority measures indicated in the 14th Medium-Term Management Plan (fiscal 2021–2023), the one directly linked to the technology field is the “commercialization of original technologies.” Over the years, we have created original products such as Aisareru Seat4 and INNOVAGE.5 By further accelerating these efforts, we aimed to develop appealing products to meet latent customer needs and secure future revenue streams.

With industry trends such as Connected, Autonomous, Shared, and Electric (CASE) vehicles, as well as Mobility as a Service (MaaS), the technology required to develop products is becoming more complex and sophisticated than ever before. Accordingly, we need to develop partnerships with other companies and industries. As one such initiative, we signed a partnership agreement with ALPS ALPINE CO., LTD., in January 2022. By merging our expertise with that of ALPS ALPINE, we were able to create XR Cabin, which brings virtual reality (VR) technology to car seat technology. By considering various situations and ways in which users might want to spend time in vehicles, we have embodied the new value required for each scene as a cabin that allows users to experience the future of vehicle interior space and our future technologies by using seats and VR images linked to them. Moreover, through joint research with other industries and start-up companies, as well as industry–academia collaboration, we are developing technologies and products that go beyond the conventional vehicle seat concepts. By doing this, we hope to expand our commercial rights in the area of next-generation vehicles.

As for the nearer future, we have been conducting R&D seeking to improve the product value of seat frames, our main vehicle seat component. Our next-generation seat frame represents a further advancement of the current mainstay model. The new product is one of the world's lightest and has the scalability to meet the needs of an even wider range of vehicle models. On the production side, the Group has adopted a design approach based on automation using robotics. We are confident we can maintain our competitive advantage over the long term by significantly improving production efficiency.

- 4 A seat system that combines automotive seat technology and IoT capabilities to sense occupant movements and turn the seat into a system controller

- 5 A next-generation vehicle interior space exhibited at Tokyo Motor Show 2019 that showcases the Group’s technologies for the future. These include sensing technologies to monitor occupant breathing, heart rate, and driving posture, as well as seat arrangement technology suitable for fully autonomous vehicles.

What kind of technological developments are you working on for the automobile industry, which is undergoing major changes?

Under our current 15th Medium-Term Management Plan (fiscal 2024–2026), one of the priority strategies is “securing cabin coordination capacity.” We are further accelerating R&D to realize future interior spaces like the one demonstrated with XR Cabin. In an era where vehicles are no longer just a means of transportation, and where travel time has become a valuable resource, we aim to become a company that can offer not only car seats but entire vehicle interiors that allow occupants to pass the time with even greater comfort. This does not mean that we are seeking to expand our business into all kinds of vehicle interior components. Instead, we are collaborating with companies in other industries and combining our strengths with theirs to create appealing cabins based on advanced seats.

Automakers and other companies are currently exploring how needs can be met in terms of ways to spend travel time, when next-generation vehicles such as fully autonomous cars become mainstream. Through these cabins, we are proposing new ways for vehicle occupants to spend their travel time. By making automakers and end users think, “Oh, this is a new kind of experience,” we hope to uncover their latent needs. Additionally, the numerous advanced technologies installed in the cabin can also be delivered as independent systems. By allowing each technology to be adopted for mass-produced vehicles as needed, we are also aiming for steady business growth at the moment while focusing on the future.

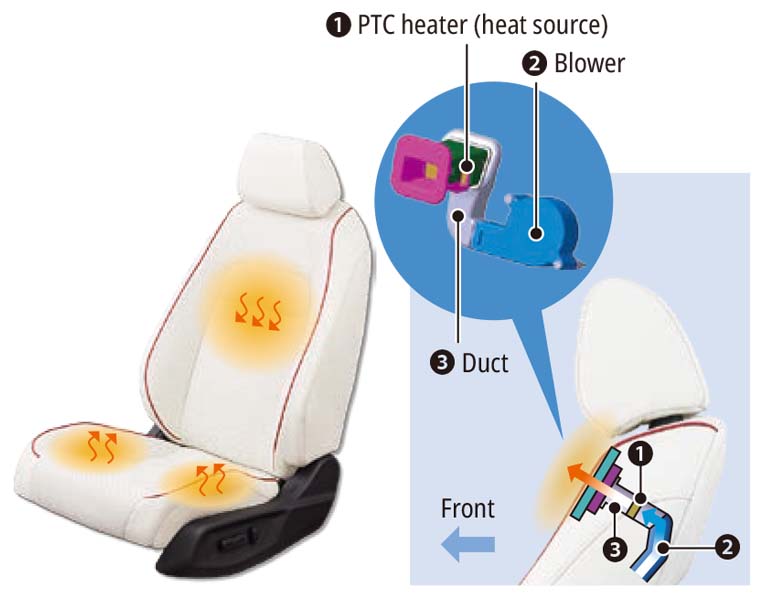

When looking ahead to next-generation automobiles, equipping EVs is also becoming an important R&D focus. While EVs will still need seats, their form and function will need to change from those used in combustion engine vehicles. One necessary change will be to make the seat profile thinner. In EVs, the battery is installed under the vehicle floor, which increases the floor height. Additionally, the height of the roof will need to be lowered in order to reduce air resistance and improve the cruising range. Therefore, EVs’ interior height (distance from the floor to the ceiling) will be lower than in conventional vehicles. In order to maintain as much space as possible inside the vehicle, the seats will have to have a thinner profile than before. We are promoting R&D to better meet these needs while maintaining safety and comfort. This is being done from various perspectives, such as changing the seat frame construction, the shape of the cushioning material, and each material itself. Moreover, we are working on developing technologies and products that will help extend the range of EVs. While using the weight reduction technologies that we have developed over the years, we are also devising energy-saving heating technology that balances comfort with lower power consumption. This is done by concentrating heating on the neck and thighs where people can feel warmth most easily.

The Group is also accelerating the development of biosensing seat technology that could become another product strength in the future. Our Health Care Seat, currently under development, automatically detects the posture of the occupant when they sit down, and it massages their muscles accordingly, thereby encouraging ideal posture. The seat can also measure vital signs such as the occupant’s pulse and heart rate, from which changes in the physical condition can be predicted. Therefore, it is equipped with functions to support human safety and health just by sitting on it. Someday soon, we hope to bring the Health Care Seat to the market.

Products in Development

As technological innovation advances at ever increasing rates, the need for interior space will continue to change dramatically. In any case, we believe that the human comfort that TS TECH has always worked to deliver will remain in demand. By further refining the core technologies we have developed over the years and by combining them with expertise from other fields, we will carry out R&D with the aim of further improving comfort while also meeting anticipated future needs.

What challenges does the Group face for achieving further business growth?

Currently, we are using XR Cabin to present our nextgeneration technology concepts to many vehicle manufacturers. While we often get positive feedback such as, “We will definitely consider your products,” there are also quite a few comments that indicate a desire for more surprises. We have been told that many proposals from emerging suppliers are much bolder than ours, and that our concepts lack excitement in comparison. I sincerely believe that our ideas have been limited by too many practical considerations, such as ease of mass production, and have remained within the realm of conventional thinking. We need to change our approach in order to revitalize our ideas and create proposals that are not bound by preexisting assumptions of what a vehicle could be.

As part of our efforts to achieve this goal, we have established a development project team made up entirely of younger employees. Normally, the Group develops new products under Large Project Leaders (LPLs), who are very experienced managers. They perform comprehensive project management from planning to mass production. While our LPL system is great for promoting efficient product development, it leaves little room for the innovative ideas of younger employees. In contrast, the new project team's activities are focused on incorporating various forms of external expertise, and creating product proposals that break our existing molds. I am very much looking forward to the proposals they will come up with. Moreover, our various collaborative activities for the purpose of “securing cabin coordination capacity” are another way of bringing in external knowledge. In addition to co-creation related to car seats, we are accelerating open innovation and joint development with various cutting-edge companies, such as teTra aviation corp., which is developing eVTOLs. This should lead to the creation of vehicle interior spaces that go beyond the standard approach of the automobile industry.

The recent rise of Chinese automakers has been remarkable, and these companies have established unprecedented product development speeds. By working around the clock, they are able to develop in six months a product that would usually take several years. This poses a challenge for us, and we expect the speed of development to accelerate across the auto industry going forward, in order to keep up with Chinese automakers. Even under such circumstances, we have to catch up to them and surpass their development speed in order to achieve sustainable business growth by further increasing our competitiveness and licensing new commercial rights not only to existing clients but also to emerging automakers in China and elsewhere. The TS TECH Group has established development sites in each global region and has built a development system that can respond quickly and dynamically to regional needs. However, our core technology development is mostly conducted in Japan. In order to further speed up development operations, it is essential that we train engineers and strengthen development capabilities outside Japan, as well.

To do this, we will accelerate investment in our “people,” including the training of engineers, not to mention our efforts to enhance development capabilities in each country, including aggressive investment in automation and efficiency improvement systems utilizing AI and IoT, exchange of technical support between Japan and overseas development sites, and expanding the size of each development site. I believe that a company’s competitiveness originates with its people, and that the key to our future business growth lies in practicing TS TECH’s corporate philosophy of striving to be “A company dedicated to realizing people's potential” and that is “A company sincerely appreciated by all.” As development competition intensifies, the pressure on engineers will inevitably grow. Furthermore, as soon as the development of one model is completed, our engineers must immediately begin work on the next model, as they strive to fulfill their mission of relentlessly achieving ever higher performance. In addition to initiatives that are directly linked to model development, such as developing and securing highly specialized human resources, including expanding specialized training in areas such as digital transformation and actively recruiting mid-career personnel, we will continue to invest generously in “people.” This means fostering workplace environments where each individual can feel motivated, and work with enthusiasm, such as creating a system to properly evaluate and compensate engineers.

For suppliers like us, technological strength forms the basis of sustainable business growth and rising corporate value. By nurturing the human resources that support our technological capabilities, and by fully utilizing the seat manufacturing expertise and passion for product creation that TS TECH has developed since its founding, we can achieve even greater business growth. We have the ability to provide even more new value to the automobile industry, which is now undergoing a once-in-a-century transformation.