Corporate Development and Engineering Officer Interview

How would you rate fiscal 2024?

The TS TECH Group is constantly striving to develop technologies that surpass customer expectations and deliver excitement to users. The automotive industry is currently in the midst of a once-in-a-century transformation. During our next-generation vehicle interior presentations held in fiscal 2023, we proposed new value for next-generation vehicle interiors to both Japanese and international customers, focusing on the advancements in electrification and autonomous driving.

Fiscal 2024 was the first year of our 15th Medium-Term Management Plan (fiscal 2024–2026). During this fiscal year, we delved deeper into customer demands and potential needs and accelerated the development of next-generation seat technology. This has been a year in which our efforts to develop next-generation technologies began to bear fruit, as some technologies that were initially developed for models our customers planned to sell in 2029–2030 were adopted ahead of schedule. Specifically, our customers have adopted technologies related to Advanced Driver Assistance Systems (ADAS) that utilize vibration devices built into the seats, and Active Ventilated Seats (AVS) that maintain a comfortable seat temperature while keeping costs lower than conventional products. I believe this is the result of our efforts to meet customer needs and pursue technological development.

We are working on various measures in the area of technological development. We have set “securing cabin coordination capacity” and “enhancing efforts to develop environmental technologies” as priority strategies in our 15th Medium-Term Management Plan. “Securing cabin coordination capacity” means transforming the Group into an enterprise that offers not just car seats but entire vehicle interiors that allow occupants to pass the time with even greater comfort. This is being promoted in cooperation with our main customer, Honda Motor Co., Ltd. We aim to create attractive next-generation vehicle interiors that exceed our customers’ needs by accurately ascertaining their strategies and demands for next-generation vehicles and leveraging our ideas and proprietary technologies to meet them.

Under the direction of our New Business Management Division, the Group is developing strategic sales activities which target customers around the world. We are working hard to expand orders for commercial rights by leveraging the technologies and know-how on seat arrangement that we have amassed over the years. In fiscal 2024, we began manufacturing rear seats for Suzuki Motor Corporation’s new SPACIA. Starting with this, we will strive to acquire further commercial rights by making technological proposals that take the needs of our customers into consideration, even more than ever before. We will also cooperate more extensively with Suzuki in the Indian market, which is expected to grow in the coming years.

Automakers are carrying out production activities in collaboration with suppliers from diverse backgrounds in different parts of the world. Therefore, an approach that blindly targets all model types is unlikely to lead to the acquisition of new commercial rights. In the past, our aims were too broad to enable us to acquire new rights effectively. Through a strategy of selection and concentration on key projects, we want to develop more effective measures, such as specific technical presentations using customer vehicles, while carefully assessing the likelihood of acquiring those rights.

We are also seeing a positive response to early product adoption in environmental technology development. The Group has been working on developing sustainable seats with low environmental impact that are made with plantderived raw materials for some time now. But problems such as changes in seat comfort and increased costs have been barriers to practical adoption. We have been working on developing seat structures to resolve these negative aspects, and as a result, we have now reached a stage where our customers can narrow down their target vehicle models and consider adopting sustainable seats in a positive manner.

Please tell us about the technologies and products that are the foundation of the TS TECH Group’s competitiveness.

The Group is carrying out R&D activities with a focus on safety, the environment, and the creation of attractive products, in order to create the vehicle interiors of the future.

We are proud to have consistently led the industry in safety, which is a top priority for manufacturers involved in vehicle manufacturing. To be specific, we were the first in Japan to adopt a dynamic sled testing facility which accurately reproduces the impact that occurs during a crash, and we have pursued technology for protecting the safety of vehicle occupants ever since. In the 2000s, we developed Active Headrests*1 for our main customer, Honda Motor Co., Ltd., making a significant contribution to improving safety during collisions. Thereafter, we accelerated research and development of frame structures to improve safety, and now our products boast world-class safety performance. All vehicle models equipped with our products receive the highest seat safety ratings in automotive assessments worldwide.

Concerning the environment, we are striving to reduce our environmental impact on two fronts: materials and structures. For materials, we are working to shift to monomaterials*2 and the application of sustainable materials (plant-derived raw materials) which do not use fossil fuels. In terms of product structure design, we aim to promote recycling by creating structures that are easy to disassemble. Although various components are attached to seats, by modularizing components—including harnesses and other parts—we aim to continue creating structures that can be easily disassembled.

To create attractive products, we are striving to accurately grasp the needs of the times, such as the shift to EVs, and working on a variety of themes for providing even greater comfort.

The shift to EVs is changing the requirements for vehicle seats. For battery EVs with flat floors, we have developed a technology that allows two seats to be mounted on a single extended slide rail, making it possible to freely arrange the seats and create a space where passengers can relax as if in a living room.

- In the event of a rear-end collision, the headrest automatically moves forward to greatly minimize neck injuries. It is activated by the force applied to the seat by the occupant’s body being pushed backward.

- This means a single material. Making products and components out of a single material greatly improves recyclability.

This significantly increases the range of movement of the seats, and makes it possible to create large spaces no matter where you sit with just a simple operation. For EVs, technology to reduce air resistance while driving is also important for increasing electric mileage. The Group has developed low-profile seat rotation mechanism components that facilitate more streamlined vehicle designs with reduced air resistance. In addition to being more compact (smaller diameter) than conventional components, they are 30% thinner and are designed to provide a lot of leg space without needing to raise seat height.

The Group is also pursuing products that create new value for time spent inside vehicles. One of these is our Health Care Seat, which helps passengers maintain their health as they simply sit on it. Equipped with biosensing technology, the seat automatically recognizes the occupant’s posture when they sit down, massages their muscles to encourage ideal posture, and measures their vital data (pulse and heart rate) to predict changes in physical condition. We will develop more realistic marketing strategies that resonate with users’ emotions and encourage early product adoption.

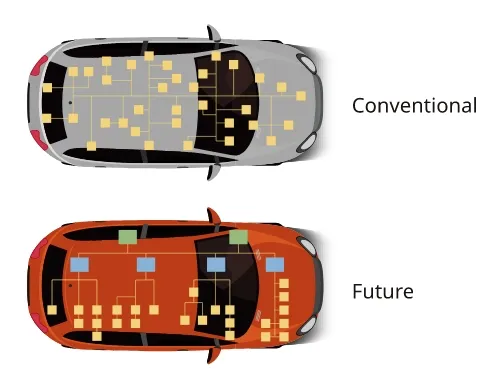

We will continue to refine the attractive products we have introduced and aim for their full-scale commercialization. However, there is an issue that we must address in order to take maximum advantage of our attractive products and secure cabin coordination functions to help expand our business. That is strengthening our system development capabilities. Specifically, we need to acquire the technology to create the Electronic Control Units (ECU) which control equipment within the cabin, such as seats and air conditioners. Today, cars are equipped with a large number of ECUs to manage the various systems and equipment on the vehicle. Of these, we aim to supply ECUs which can control components related to seats in an integrated manner. Integrated ECUs are highly anticipated by automobile manufacturers for their ability to control many pieces of equipment from a single device, to help reduce weight and the number of wiring harnesses, and to support updates. As we move forward with development projects for each automobile manufacturer, we aim to work smoothly with solution providers who have a close relationship with each company to develop integrated ECUs. With the ECU business, we also envision a business selling software, not only hardware as we have in the past.

What is the TS TECH Group doing to improve the quality and efficiency of development?

For the Group to sustainably create attractive products, we will need to ensure our development efforts leverage highly reliable systems and mechanisms. The way development work should be conducted is changing as work styles diversify with the shifting times and environment. But for a manufacturer closely involved with the safety of vehicle occupants, quality is the most important goal. Verification work at the design stage is essential for improving the quality of development. Accordingly, we are strengthening verification of layouts by experts in various fields. These efforts are based on the Three Reality Principle,* under which field experts thoroughly verify functionality, safety, comfort, and cost during the development stage. This leads to increased development quality.

In addition, we are working to improve the efficiency of design work through digital tools. We have introduced a system that links information about past problems and examples of failure to the latest 3D CAD tools. This allows the people in charge to proceed smoothly with design. In the future, we would like to work on reforming development management work, which holds the keys to success in development projects. We are putting in place a system to improve the efficiency of development management by visualizing the time and cost associated with the series of processes that make up product development from design, through prototyping, to testing.

- A way of thinking that comprehensively analyzes problems from the perspective of the Three Realitiy—on-site, actual things, and reality—to identify solutions and implement improvements

What are the goals and challenges for fiscal 2025?

For fiscal 2025, we want to create high-value-added products by focusing on the Group’s core areas of seats and door trims. To roll out more effective development and sales activities, we will narrow down our target commercial rights while considering the whole interior space, create convincing samples, and propose spaces with stories that allow us to envision the joy of the users.

We will also strengthen our local development system with the goal of remaining competitive in China, where competition is intensifying. To not only support our customers’ business strategies in China but also to meet the quality and speed demanded by local automakers, we will create and implement a development structure centered around local personnel in China. We have already acquired commercial rights from new customers there, and plan to further enhance our development system to increase orders.

Furthermore, the most important event from the standpoint of development strategy is our 2024 next-generation vehicle interior presentation, scheduled to be held in November. At our previous presentation, we received generally high praise from the automobile manufacturers we invited, and some went on to adopt our products. However, we also received quite a few comments that our products lacked originality and the sense of excitement surrounding some emerging suppliers.

At our next presentation, we plan to exhibit a new value proposition based on this feedback and embodied in an actual vehicle. We want our guests to make new discoveries and experience the interior space of vehicles like never before.

What are your thoughts about the human capital responsible for manufacturing?

One of the Group’s vision statements is to be “A company dedicated to realizing people’s potential,” and we are focused on recruiting and developing personnel to support our corporate growth. To continue to create new value and develop sustainably going forward, we need to build a stable foundation for development activities by securing both the quality and quantity of personnel we need. This includes not just young people but all age groups. However, it is not easy to attract people with specialized skills. As you may know, there is high demand not only for people in mechanical and electrical fields but also for those in systems and software fields with skills related to ECUs, which we want to pursue going forward. We must actively consider new work styles and working conditions to enhance our ability to attract superior talent. In addition, based on our strategy of growing orders by obtaining new commercial rights, we believe that efforts such as flexible allocation of development sites will have a positive impact on attracting talent. As we strive to recruit new talent, it is also vital that we make sure the people already working at the Group are able to make the most of their abilities. We plan to renovate our development sites to improve their work environments and increase the speed and quality of development.

We believe that companies like ours must increase the diversity of human capital responsible for manufacturing in order to enhance their ability to create value. Since a wide array of skills will be required for making seats from here on out, we intend to actively invest in personnel in areas that we were not involved in before. In doing so, we aim to become a company that can make proposals that are more relevant to customer needs around the world than ever before.