Special Feature 1: Special Discussion

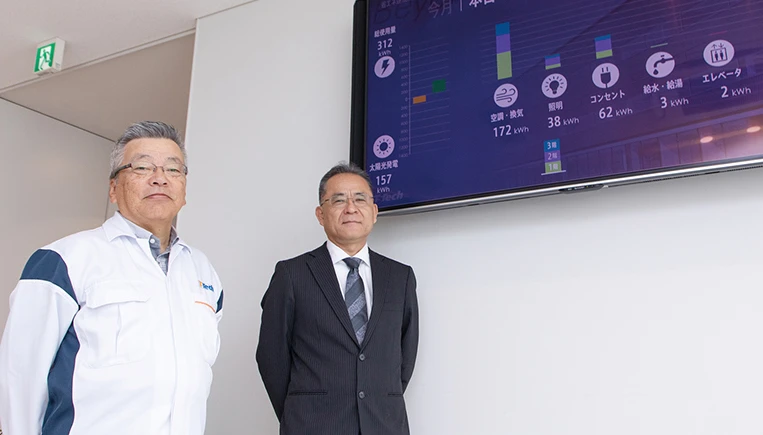

The TS TECH Group sees environmental performance as a key management issue and constantly strives to make improvements in this area. As a part of these efforts, the Group acquired ISO 50001 energy management system certification at all locations in Japan in March 2019. Upon adoption of ISO 50001, Yoshitaka Nakajima, Executive General Manager of the Corporate Administration Division—the department that oversees the Group’s environmental initiatives—sat down with Junichi Shimizu, Director of the ISO Registration Center at Japan Electrical Safety & Environment Technology Laboratories (JET), the organization which conducted the certification review, to discuss the Group’s environmental initiatives.

The Evolution of TS TECH’s Environmental Initiatives

- Shimizu:

-

As a certification standard related to environmental initiatives, the aim of the ISO 14001 environmental management system (2015 version), for which your company originally obtained certification, is to “continuously improve initiatives aimed at reducing the environmental risks that arise from corporate activities.” It places an emphasis on building and managing a PDCA cycle for those initiatives. On the other hand, the ISO 50001 energy management certification (2011 version), which you recently acquired, aims to “make energy consumption apparent, establish policies, objectives, and goals necessary to reduce consumption, and conduct efficient and systematic management.” Making both the current situation and the results of improvements visible clarifies various aspects, which helps to move environmental initiatives forward.

- Nakajima:

-

Making energy consumption visible certainly makes it easier to set very precise goals and creates momentum to keep moving forward. It has also brought new issues to light. At our company, our administrative department has served as secretariat, compiling documentation on environmental initiatives and their energy-saving effects at all companies, but now this work has crossed into highly specialized territory, such as energy management techniques. As we improve our endeavors going forward, we believe the divisions that manage facilities and equipment should take the lead. Furthermore, environmental activities must be sustainable, so it is, therefore, important to conduct efficient operations and capital investment by setting long-term goals and strategies, just as we would for our business activities. By being consistent with our initiatives and efforts, we can develop a routine that becomes common practice.

- Shimizu:

-

Exactly. If environmental initiatives are perceived as “common practice” rather than “something special” within your company, I think the scope of your activity will expand.

TS TECH’s Environmental Initiatives

- Nakajima:

-

One of our environmental goals is the rate at which we reduce energy consumption; for the most part we have done all we can to reduce energy consumption over many years. Going forward, we hope to pursue environmental initiatives in collaboration with our suppliers. Since further management costs and resources become necessary when the scope of activity broadens, we plan to move forward strategically while cooperating with the relevant divisions. We are currently working on an environmental vision that provides specific medium- to long-term goals for environmental issues. To achieve these goals, we must use the perspectives gained through the acquisition of our certification as useful tools to create a ripple effect that impacts not only our Japanese operations and Group but our supply chain as a whole. Conceivably, environmental initiatives will no longer simply be improvements to the current state but become equivalent to organizational reforms. Each and every employee must be thoroughly aware of his or her own role in this. Pursuing environmental initiatives through the involvement of every employee requires considerable courage, but it will be necessary from now on. Even when we no longer have to think twice about making improvements, we must continue to change our awareness of what lies beyond improvements—what can be called environmental reform.

As a manufacturer, we must make advancements at all stages, from R&D through materials procurement and production. We hope to conduct versatile environmental initiatives, including developing eco-friendly materials and decreasing energy consumption through weight reduction and improved production efficiency. Of course, we think that it is best not to rely solely on our own company’s resources but to develop these initiatives in a flexible manner while incorporating elements such as open innovation.

- Shimizu:

-

It is wonderful that your company has worked on these issues for so many years. Your early commitment to energy management can also be considered forward-thinking. However, you have just embraced a new energy management system, and it will take time to roll it out to all worksites. I think that the period after certification acquisition is crucial, so I hope to see you keep working at it. I agree with your view that reform that goes beyond improvements is necessary. It is difficult for a private company to balance that kind of ability to respond to society with its core businesses, but I certainly hope you will make the most of the ISO certification.

Impressions of TS TECH Based on the ISO Review

- Shimizu:

-

In the course of reviewing your company, I held interviews with many people—from those in charge of acquiring the certification to those in management—and I was impressed by everyone’s high level of motivation. Although each individual’s role and manner of involvement differed, it was admirable that everyone fundamentally shared the ambition to implement even better initiatives. At the same time, I was struck by the fact that, while a management system for all companies was in place, the distinct characteristics of each office were taken into account. Since an ISO is a standard it has uniform management methods, and there is a tendency to think the recommendation is to apply those uniform methods across the board, but because a company is an aggregate of various divisions, each location is, naturally, unique. I saw each of your locations look for measures on their own, valuing their specific facilities and established cultures while simultaneously working toward the shared goal of acquiring ISO certification. This uniqueness seems to be the energy driving each individual. I think that leading without forcing standardization, yet not losing a sense of solidarity, is extremely difficult, but TS TECH is deftly managing this feat.

- Nakajima:

-

Each office, including the secretariat, is doing a good job, and for this I’m grateful. Though we may refer to our company’s plants in broad terms, the seats we manufacture have extremely sophisticated structures and numerous components. Different vehicle models require different manufacturing methods and materials, so, in reality, it’s impossible for all offices to be managed identically. I think it’s interesting when each office takes the initiative to showcase its individual characteristics. However, viewed from a global perspective, there are still discrepancies in terms of degree of commitment. We have plans to apply the management techniques established in Japan through acquisition of ISO 50001 to overseas locations in the future, but I wonder if they truly possess the same level of determination that we have. There are still some locations that aren’t fully autonomous, so until they get on the same track, I think the parent company in Japan has to take the lead. Even if it takes time, we will not only promote management methods but also sufficiently share our ideas on the environment with every single employee at every location in every country.

- Shimizu:

-

I believe it will take time, but first it is important to make sure that what you have started will take root. If you can do that, in due course you will be successful. At this moment, not very many Japanese companies have acquired ISO 50001 certification. I hope the success of your company’s endeavors will increase the acquisition of certification in Japan.