Mar. 18, 2024

Introduction of new models

Seats that incorporate a wide range of technologies to give all users the “good life”

Honda STEP WGN

The Step WGN released in May 2022 features seats developed by our company.

From the driver’s seat to the third-row seats, minivan seats need to meet a range of different performance

requirements. We asked project members about their pursuit of not just safety and seat comfort but also

outstanding interior comfort and convenience during the development of these seats.

Profile

-

Hiroyasu Tsunagawa

Model LPL Office

LPL(Large Project Leader)

Joined TS TECH in 1988. Assigned to a factory after joining, then gained experience in the product testing department and other divisions. After returning to Japan in 2016 following a third stint overseas, worked on and led projects for various models as the LPL.

-

Koji Fukuhara

Design Department 1

Design PL(Project Leader)

Joined TS TECH in 2001. Assigned to the Design Department. Oversaw the development of all three rows of seats, each with different performance requirements, as the Design PL for the new Step WGN.

-

Kazunori Hojo

Development and Testing Department

In charge of development of second-row seat layout

Joined TS TECH in 2011. Assigned to the Development and Testing Department. In charge of developing the layout of the second-row seats, the key to interior comfort in the new Step WGN.

-

Tatsuya Sugita

Electrical Device Development Department

In charge of power supply unit development

Joined TS TECH in 2014. Assigned to the Electrical Device Development Department. In charge of in-house development of the power supply unit that was installed for the first time in the new Step WGN.

What is the concept behind the development of these seats?

TsunakawaSince its first-generation model, the Step WGN has been a favorite among users as a tool used by families to enrich their lifestyles, rather than simply a mode of transport. With this in mind, we began development in line with the grand concept of "good life" specified by our customer (Honda) for this model. The requirements for seats that fit the “good life” concept were interior comfort much like a living room at home and a high level of convenience to accommodate a broad range of possible scenarios. To meet these requirements, we focused on making sure the seats could be configured in a variety of layouts to give each member of the family their ideal seating style, as well as ensuring that the seats could be adjusted easily when getting in and out of the vehicle.

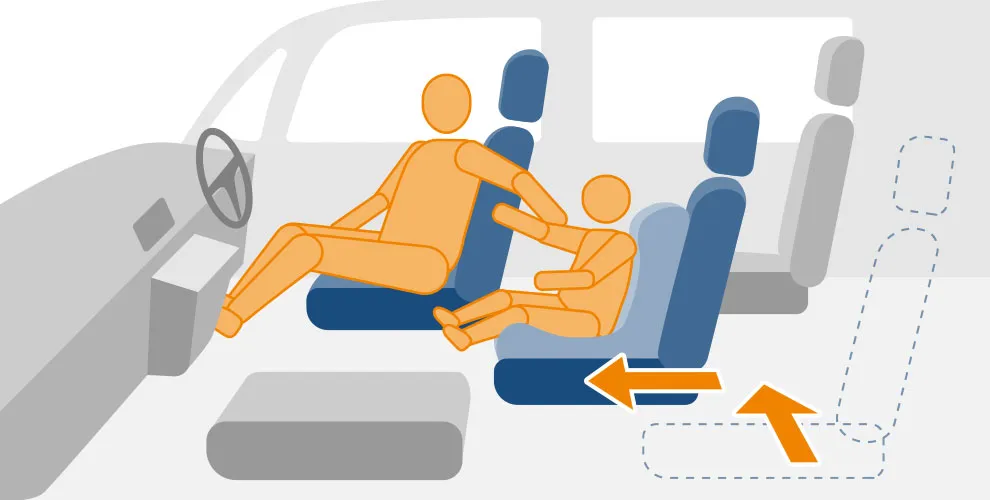

Families constitute the bulk of Step WGN users, and they have a wide range of needs. We had various types of families and usage styles in mind, and we incorporated a lot of feedback from users of past models into the development process. In many cases, minivans like the Step WGN are driven by mothers with young children sitting in child seats in the second row. Many of those mothers told us they wanted to be able to keep an eye on their children while driving. To make this possible, we made the front/rear slide mechanism about 250 mm longer than the previous model and also added a new sideways slide mechanism. This means the seats can be arranged in a layout (Diagram 1) so that children are within reach and easy to keep an eye on. In cases like this, the mother is usually the one who moves the second-row seats, so we designed the seats so they can be adjusted easily by anyone. During development we also envisioned situations such as “theater mode,” where the passengers slide the second-row seats all the way back to relax and watch a screen installed on the ceiling.

FukuharaIn addition to enhancing their features, we also designed the seats to be highly cost competitive. Rather than designing new seats completely from scratch, we retained the basic specifications of the popular seats in the previous model and incorporated minor modifications to suit the new Step WGN. This helped to avoid excessive costs, not only during the development phase but also during the production phase when the seats are mass-produced. More specifically, the front seats were designed using our "next-generation seat frame*," while the third-row seats retain the basic design of the previous model. The original designs for both incorporate a versatility that enables them to be used in a range of models, but partial design changes and testing were necessary to ensure that they met the requirements for seats for the new Step WGN. From a design perspective it may have been easier to make new seats specifically for this particular model, but reusing existing designs helped to keep the seats cost competitive.

* A seat frame used in a wide range of seats for everything from compact cars to SUVs that is 28% lighter than previous models through modified materials and welding methods

What are the characteristics of each type of seat?

FukuharaThe front seats use the next-generation seat frame that is praised for its ride comfort, and the angle at which the seats are mounted to the chassis has been tilted back by 2° compared to the previous model. This lets passengers sit further back in the seat, allowing for a seating posture that creates less fatigue. The result is a greater level of comfort for the driver, despite being a minivan that is usually used as a family car. The seat heaters also feature a "rapid heater*" for added comfort in winter.

* A heater system that heats passengers faster with a lower level of power consumption

We worked to improve the comfort of the third-row seats, which retain the functions of the popular "Magic Seat" (Diagram 3) from the previous model. The thickness of the seat cushion has been increased by 20 mm, but the resulting change in seating position had an adverse effect on safety. To overcome this, minor changes were made to the seat shape, cushion firmness, frame position, etc. during repeated testing to ensure better ride comfort while maintaining safety levels.

What features have been included in the second-row seats?

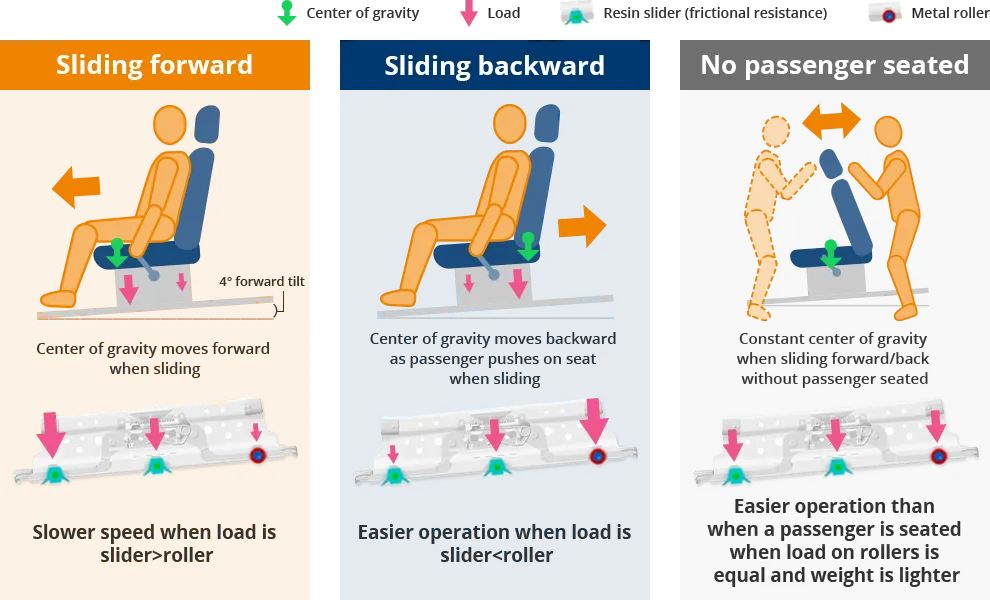

HojoA sideways (left/right) slide mechanism is featured for the first time in the Step WGN, giving users greater flexibility to arrange seat layouts for more functional cabin space. The seat can be adjusted in the front/rear and left/right directions with a single lever, eliminating issues arising from accidentally using the wrong lever. Being able to slide in both directions with a single lever tends to make the lever stiffer to use, which affects the convenience offered with such a function. To combat this, we altered the surrounding structural components to achieve a lighter feel when sliding the seat forward or back, and a slightly heavier feel when sliding it sideways. The different lever feel depending on the direction of adjustment helps to make operation more intuitive (Diagram 4).

Our design expertise has also been incorporated into the lever feel when sliding the seat forward and back. A key point of the previous model was a light lever feel that made it easy for anyone to operate. While this was a popular feature, some users were concerned about how quickly the seat moved forward when sliding the seat while seated. To address this issue, we modified the roller-like components found at the base of the seat and used a special rail that limits the speed when the seat slides forward, yet still makes seat adjustment light and easy when sliding it in both directions without anyone seated or when sliding it backwards while seated.

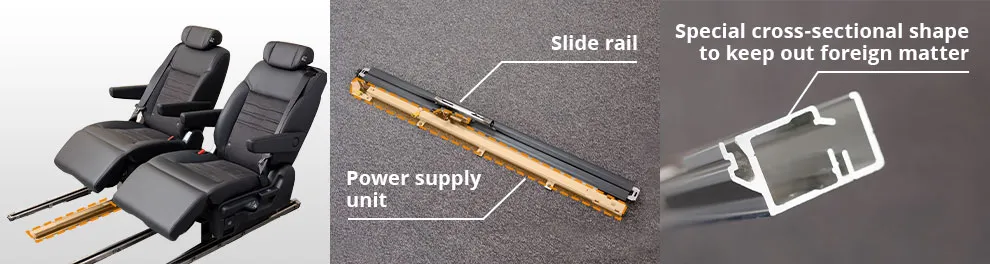

SugitaNot only were our seats themselves used, a power supply unit that was developed in-house was also used in the second-row seats. The unit itself is a rail-shaped component that is installed on the cabin floor next to the slide rail. This is the first time such a unit was developed in-house, and we went through repeated trial and error to make sure that it met the performance requirements of our customer. As it is installed on the floor, it needed to be durable and have the ability, for example, to withstand being stepped on by high-heels or to continue to function when exposed to juice or snacks. Of particular concern was the risk of a fire if liquids enter sections of the power supply unit containing live electricity. To avoid this, the unit was designed to allow substances to run out freely in the event of spillage (Diagram 6).

This power supply unit is 65% lighter than those made by other companies, and the rail cross-section is 56% smaller, making it ideal for in-cabin installation. We also designed the unit based on the possibility that it would be installed in other models in the future by including sections that can be upgraded to supply sufficient power for full-spec seats with a large number of electronic components. As autonomous driving becomes even more advanced and electric vehicles gain popularity in the future, the types of features that will become available within a car's cabin will also continue to evolve. As such, the significance of components other than the actual seats themselves is expected to grow. These seats in this model were outfitted with our power supply unit, and we believe that gradually being able to increase the range of components that we can offer our customers will translate into one of our strengths.

What other types of technology were used?

TsunakawaThe inclusion of the sideways slide function means that the seats feature integrated seat belts, and we used a frame on which development had already started for the newest second-row seats. This type of frame has the seat belt mounted to the seat itself instead of the body of the car, but this design presents a challenge as it needs to be made heavier than ordinary types in order to be strong enough. To address this challenge in our newest frame, we overhauled the shape of parts and the base structure, changed materials, and kept thickness to the minimum needed to achieve the required strength. This made the frame around 28% lighter, a significant weight reduction compared to existing types of frames with similar functions.

FukuharaSome grades are also equipped with a rapid heater in the second-row seats, as well as a footrest, the first such feature for this particular model. The footrest has a broad design to match the seat base, providing a much higher level of comfort when sitting back relaxing. Our customer praised the footrest specifications during the development phase, and it has also proven to be a popular addition among users.

We have also been mindful of safety from the user's perspective and included a number of subtle structural designs. Sliding the seat all the way forward with the footrest raised would result in a passenger’s legs becoming pressed against front seat. To avoid this, a lock mechanism has been included in the seat frame to limit forward movement with the footrest raised. The way the table is mounted to the rear of the front seat has been modified so the table flips up if a passenger makes contact with it. In particular, the table is around the same height as a child's head, so we made sure it was designed to prevent injuries in case children hit the table (Diagram 7). While seat safety usually focuses on the level of protection afforded to passengers in the event of an accident, these two features represent our commitment to safety by demonstrating how thoroughly we study the potential dangers in a variety of cases.

TsunakawaLooking back, there were times where the project wasn’t going smoothly as it was a challenge just to get together with project members when COVID-19 was spreading during the development phase. Yet we were able to think about the best ways to overcome the challenges we faced and maintained our lines of communication so that we could press on with development through to a successful completion.

We all thought hard about how we could achieve our customer's requirements of lighter weight, space efficiency, and cost competitiveness, while keeping in line with the "good life" concept. By incorporating a number of our company's key technologies, I am confident that we achieved a level of safety and comfort that easily surpasses that of other companies. I think the seats offer users an unprecedented level of safety and comfort, and everyone should experience for themselves the luxury and protection that these seats bring to the cabin. I hope that these seats play a role in creating a "good life" for all users.