Mar. 18, 2024

Introduction of new models

A rear seat that is comfortable and convenient during both standard and assistive use

Honda N-BOX Rear Seat

Making the N-BOX more comfortable and convenient

A vehicle loved by users for reimagining the minicar,

the new Honda N-BOX was the best-selling car in Japan in fiscal 2017.

TS TECH oversees everything from development to production of rear seats for the N-BOX.

We asked some key members involved in the development of this seat about its new value creation.

Profile

-

Mutsumi Tanaka

Product Engineering Department

General Manager

*Model LPL Unit LPL (Large Project Leader) at the time of development

Joined TS TECH in 1986. After being assigned to the Development and Testing Department, he worked with prototypes following a stint in the New Product Development Department. After serving as manager for a section in charge of prototypes, in 2010 he was assigned to the Model LPL Department, where he oversaw the launch of models as the LPL. In April 2018, he was transferred to the Product Engineering Department, where currently he serves as General Manager.

-

Shota Sunaba

Design Department

Slope Specification Design PL (Project Leader)

Joined TS TECH in 2011. After being assigned to the Design Department, he was put in charge of designing special seats and MMC (minor model change) projects. This was his first time serving as the Design PL for a FMC (full model change) project.

Tell us about the development of the new N-BOX rear seat.

It was hard work. (wry smile) I initially thought that it would go smoothly because we had made good progress on the pre-development for the order. However, we had to re-develop the seat from scratch in order to meet additional requirements from the customer (Honda). Also, irregular problems such as the need to newly develop a headrest guide*1 occurred right before mass production, but with the outstanding support of the Suzuka Plant, which is responsible for production, we were able to make it to the mass production stage.

*1 A mechanism that adjusts the height of the headrest

What has evolved from the N-BOX SLASH rear seat for which you were an LPL?

The three conditions (points of evolution) for the new N-BOX rear seat development were to make a product that is "light, low cost, and thin."

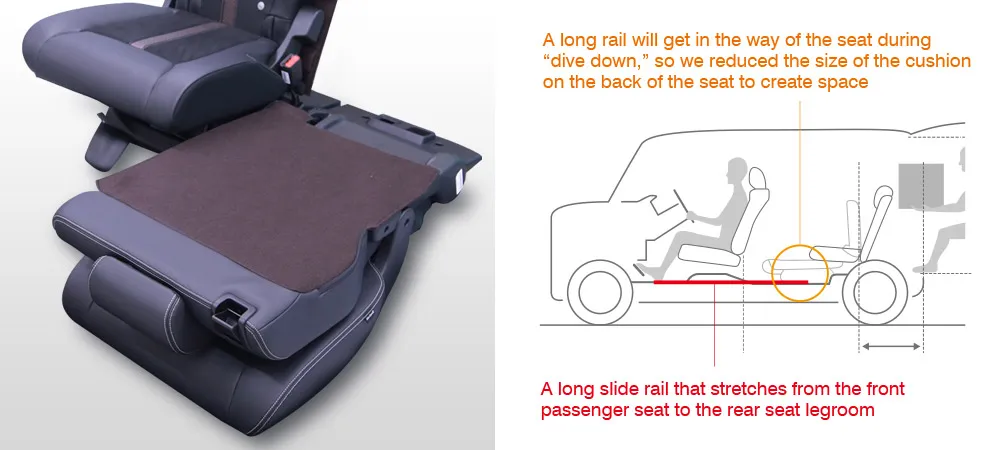

The most difficult of these was to make the seat "thin." Since the seat arrangement is the same as the N-BOX SLASH (hereafter "SLASH"), it is hard to see what we changed visually, but we reviewed everything about the seat frame, including the slide rail accessory parts. Unlike the SLASH, the selling point of this vehicle is a luggage compartment that can easily accommodate a bicycle with child seat (a standard 27-inch wheel bicycle), so we tried to maximize the interior height as much as we could. A long slide rail was added to the front passenger seat during development, which meant that we had the difficult challenge of making the rear seat even thinner for "dive down*2." So, we used trial and error to meet the customer's request of ensuring the same size luggage compartment as the previous model (which did not have a slide mechanism).

Delivering a seat that was both strong and thin was more difficult than we imagined, and we took measures that would keep costs down, so while we unfortunately could not meet the initial goal for a "light" product, we tried to reduce weight as much as possible.

To achieve "low cost," we simplified the rail and foot pipe mechanisms to reduce the number of parts. Thanks to the cooperation of many people, the new N-BOX delivers a seating space and a luggage compartment not previously found in minicars. We really want all end users to experience this rear seat that aims to be both comfortable and convenient for themselves!

*2 A mechanism that causes the seat cushion to lower when the seatback is folded forward

Please tell us about your passion for manufacturing!

There is an idea that we cherish when developing models. That is, "Don't just do it because the customer (OEM) said to do it; put yourself in the shoes of the people who will use the product.". Also, we are challenging ourselves to develop models with the awareness that we are not making a seat in isolation but rather we are responsible for producing a part of a car.

What kind of model is the slope specification?

Unlike the standard N-BOX, this model features a luggage compartment floor that turns into a slope when pulled out, so it can be used for everything from caregiving to hobbies.

"Comfortable and convenient as both a standard vehicle and a wheelchair-accessible vehicle" —that is how we approached our development in order to create a product that met our customer's needs. Since it was the first time for us to design a seat that was compatible with an electric winch*3, we struggled during the initial review of ideas and the layout for this new project. Customers expect further enhancements and innovation for the functionality of cars given the diversification of automobile users and their usage environments, so the slope specification is a model that people are watching closely.

*3 A mechanism that automatically loads a wheelchair into the car

What were the difficulties and focal points during development?

Achieving a rear seat that is both comfortable when in use and can safely stabilize a wheelchair when it is stowed. Development was not easy. A certain amount of seat thickness is necessary to ensure seating comfort. On the other hand, in order to achieve a design that folds fully flat to allow someone to get in and out of the car in a wheelchair, we could not make the seat thick. How do we approach these conflicting requirements? It was a big challenge.

In addition, given that the selling point of the N-BOX is its luggage compartment, we had to make the seat strong enough so that it would not break even if it was rammed by heavy luggage. Making the seat thinner means making the steel frame of the seat thinner, too, but if you simply reduce the amount of metal, its strength will drop. Our challenge was to find a way to make the seat as thin as possible yet maintain a high degree of strength. Ultimately, we were successful in developing a seat that meets the safety standards of tests such as the bulkhead test*4, and delivers passenger comfort and convenience.

*4 A test to verify product strength when luggage in the luggage compartment collides with the rear seats in a collision

Please tell us about your passion for manufacturing!

I had the opportunity to serve as the Design PL, and the slope specification was a new challenge for both the company and myself, so I feel that I significantly enhanced my skills through the chance to be involved in this project. Development of special models consists of a long period of hard work, but I think that when we approach our work with a high level of motivation and joy, it leads to product development that gives joy to both society and our stakeholders.

I can recommend this product to customers with confidence.

The slope specification is particularly popular among customers who require caregiving. In addition to the comfort of the seat, many users comment that it is now much easier to perform the preparatory steps for loading a wheelchair into the vehicle than the previous model. Also, it was a bit complicated and difficult to explain the seat arrangement when loading a wheelchair in the previous N series, and, to be honest, this was hard on our sales representatives. With the new model, the number of seat arrangement steps has been reduced by more than half, making it easier to explain to customers (end users), so this really helps us.

Loading a wheelchair is a breeze! The slope specification is very convenient.

I am currently looking after my mother. Originally I was planning to switch from the Honda Step WGN assistive vehicle to a mini-van from "company T" with a larger interior. But I am the one who drives my mother around. I was concerned about handling a big car, and I thought it would be inconvenient when I just wanted to do a little shopping. Therefore, the N-BOX slope specification is the perfect car for me.

When I was contemplating my purchase, I brought my mother's wheelchair to the dealer and nervously tried loading it into the vehicle. I was relieved when it fit perfectly. It's been a month since we got the N-BOX, and we use it comfortably every day.