Mar. 18, 2024

Introduction of new models

The sports seat that resonates with driving enthusiasts

Honda CIVIC TYPE R

The next generation of the well-known Type R, the sportiest Civic model, was released in July 2017.

For a car that can be used everywhere from the track to the street, the right type of seat is critical to ensure driver enjoyment.

We asked some key members involved in the development of this seat about this project.

Profile

-

Naoto Sayama

Model LPL Department

LPL (Large Project Leader)

Joined TS TECH in 1987. Worked on automobile seats in the Design Department until 2001, when he was posted to the U.S. Has been involved in all project assigned models, from development to release, as an LPL.

-

Kazuya Inoue

Design Department

Joined TS TECH in 2014. Involved in seat frame design in the Design Department.

Was in charge of design for this project. -

Ryuhei Abe

Development and Testing Department

Joined TS TECH in 2013. Involved in safety testing of mass produced seats in the Development and Testing Department. Was in charge of testing for this project.

SayamaWe kicked off development of the Civic Type R (hereafter, Type R) project with the main concept that the Type R is first and foremost the ideal front-wheel drive sports car. The Civic is a very popular model that is sold worldwide. As such, ride comfort that would not disappoint the many fans of the Civic was a major priority. With the next-generation Type R, however, remaining faithful to the racing spirit of this iconic brand and establishing this car as the ultimate sports car was also critical. With development in Japan and production in the U.K., we worked closely with the Manufacturing Department at TS TECH UK LTD. (hereafter, TSUK) on this project.

InoueIf you compare the previous Type R with this latest generation, the seats look nearly identical in appearance, but their performance couldn't be more different. The seats in the new Type R are designed to support the body via its different surfaces to better keep drivers in position.

AbeThe Type R seat was developed with the notion that this car is suitable for everyday driving as well as performance on the track. As such, we did not focus solely on the seat’s ability to keep the driver in position and aimed to develop the most comfortable seat to date. Generally speaking, the Type R seat has the best of both worlds in terms of being a sports car seat and a seat for everyday driving. Attempting to take only the positives of the different, often opposing things often results in being master of none, but I am happy to say that we were successful in developing a new seat that is both comfortable and keeps the driver in position. It is truly a remarkable achievement.

Abesupport for the body, even during hard cornering, to keep the driver design, the seat also helps to prevent fatigue and maintain driver comfort during long-distance driving. During development, we analyzed the effects of G-forces on the driver while driving using three indicators: the feeling of unity with the seat, the feeling of being twisted, and dynamic body pressure.

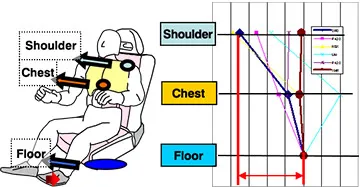

SayamaTo measure these three indicators, we used six-axis vibration excitation equipment for verification. The six-axis vibration excitation equipment can simulate actual driving states, so the effects of G-forces on the body and the corresponding effects on seats can also be simulated. Motion capture technology* was also used to analyze body movement caused by centrifugal force during this simulated driving.

For example, if the shoulder moves significantly, we know that G-forces are acting on that particular spot. This enables us to analyze dynamics in terms of the ability of the body to withstand lateral G-forces. We conducted many rounds of trial and error using these three indicators to develop a seat that satisfied both requirements of comfort and keeping the driver in position.

InoueClose collaboration between the Design Department and Manufacturing Department was essential for the mass production of a seat that is dynamic, matches the unique, attractive lines of the Type R and incorporates the red theme of the car.

As the manufacturer of this seat, TSUK functions as our production base for various seat frame specifications for the Civic.

Seat frames actually have many different shapes and configurations. Even if the basic shape of the frame is the same, different parts are attached to the frame. In this case, significant effort was required to design frame parts that would be compatible with the layouts and structures of production tools. The local employees at TSUK really deserve our thanks and a special recognition because of how they have successfully added the production of the Type R seat into their already full workload, which includes the start of production on other new models.

InoueProduction tools are normally changed along with changes in production models. However, the amount of lost time and labor costs increase as the number of models produced on a single line increases. TSUK uses automatic comprehensive welding* processes to weld seat frames. For this reason, it was necessary to devise methods of ensuring efficient production without major tool upgrades. As a solution, we decided to create tools that can also be used for other frames to produce the Type R seat using existing facilities so as to not disrupt the current production line. The Manufacturing Department in TSUK worked closely with the Design Department in Japan on this project. Thanks to open discussion with them throughout the project, we (the Design Department) were able to properly design the tools. While we sometimes disagreed on important points, this led to further discussion until both sides could agree and, ultimately, successful completion of the project.

*A method of performing all seat frame welds as a single process instead of the conventional method of using multiple weld processes

After the completion of this project

Development and manufacturing working together to

complete a project - the TS TECH Way

SayamaWe certainly had some difficulties with the actual startup of factory production, but thanks to the fast response of not just the Manufacturing Department but also our suppliers, we were able to meet established deadlines. While there were times of frustration when some of us thought this simply could not be done, even if the plant were in Japan, and wanted to delay production startup, the Manufacturing Department really pulled through and saved the day. Despite the strict scheduling, we were able to start production without any delays thanks to the efforts of everyone in the Manufacturing Department. This project simply would not have been completed successfully if it were not for the Design Department in Japan and the Manufacturing Department at TSUK working together as a team. We are all truly grateful for and certainly will not forget the efforts of everyone at the local plant.

AbeThe seats I helped develop were quite a popular attraction at the Tokyo Motor Show. I must say I was genuinely happy when I sat in the Type R seat on display at the Tokyo Motor Show.

I also felt such pride to work for a manufacturer of automobile seats when I saw our seats in the actual Civic Type R on display in the Honda booth. Seeing the actual car in person like that is certainly moving.

InoueThis is my first involvement in a mass-production model since joining the company three years ago, so this project is definitely special to me. I hope that this seat and this car really speak to enthusiasts and other drivers around the world.

I am honored to have been involved in the production of such a model.