Supply Chain Initiatives

Supply Chain Management Policy

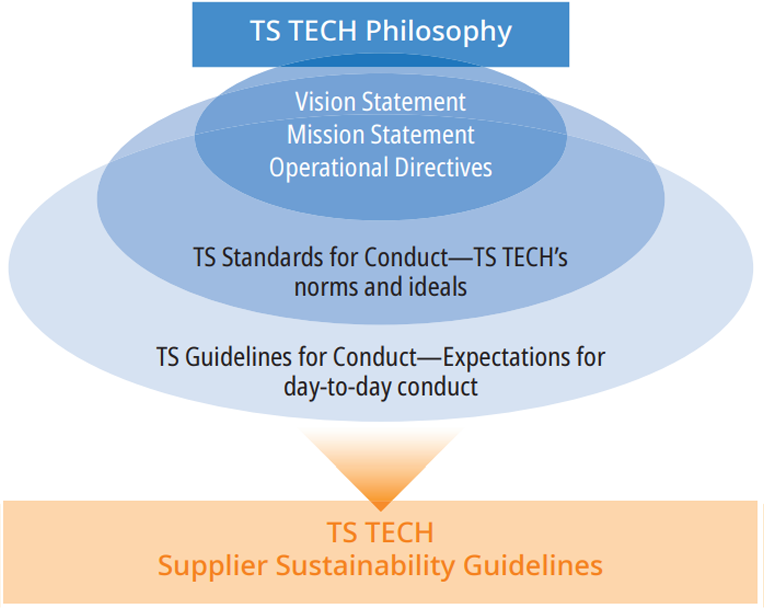

To be a reassuring presence and remain “A company sincerely appreciated by all,” there is the need to not only pursue profits through business but also to manage the company from an ESG perspective. Based on the TS TECH Philosophy, our Group aims to realize a sustainable society by promoting initiatives that take into consideration factors such as the environment, safety, human rights, compliance, and social responsibility not only within our own company but along entire supply chains.

| Category | Content |

|---|---|

| 1. Safety and Quality |

|

| 2. Human Rights and Labor |

|

| 3. The Environment |

|

| 4. Responsible Mineral Sourcing |

|

| 5. Compliance |

|

| 6. Information Disclosure |

|

Responsible manufacturing and corporate value improvements in supply chains

Centered on electrical components for automobile seats, STANLEY ELECTRIC conducts business with TS TECH on a global scale. We have been actively participating in quality initiatives based on the TS TECH Supplier Sustainability Guidelines and fulfilling our role as one link in the supply chain. As a result of these efforts, we were the recipient of the Fiscal 2025 Quality Awar d.

Having adopted “The boundless pursuit of the Value of Light” as its business philosophy, this company is aiming to contribute to society by providing all its customers with safe and reliable products. By rapidly responding to collaborations on optical technologies and safe and secure products, we will continue to work with TS TECH in the years to come to further strengthen the partnership between our two companies. At the same time, we will bring about sustainable growth in response to major transformations and changes across the industry.

STANLEY ELECTRIC CO., LTD.

Use of TS TECH Supplier Sustainability Guidelines

Our Group has set out the TS TECH Supplier Sustainability Guidelines to share and co-promote our approach to sustainability with our business partners. Having established requirements in six areas—Safety and Quality, Human Rights and Labor, The Environment, Responsible Mineral Sourcing, Compliance, and Information Disclosure—we request that all our business partners comply with the guidelines.

These guidelines are posted on our website and shared with all our business partners, both in Japan and overseas. We also use questionnaires to verify the compliance status of our business partners, and in fiscal 2025, surveyed more than 600 companies at home and abroad. Recognizing this initiative as one of its material issues, the Group continues to implement the questionnaire procedures on a yearly basis while working to build a sustainable supply chain by, for example, checking the status of individual business supplier companies with low compliance rates.

Basic Policy on Procurement

The TS TECH Group’s products are made from a wide variety of materials and components provided by its suppliers. In order to reliably offer quality products at competitive prices to our customers, solid partnerships with our suppliers are indispensable.

To realize fair and equitable transactions, as well as build and maintain win-win relationships with our business partners on a global scale, the TS TECH Group established the Four Principles of TS Procurement and published the Partnership Building Declaration. By putting these principles into practice, we aim to build a supply chain that is trusted by all stakeholders.

- (1) Fair Trade

- When selecting a supplier, we offer our business to several candidates irrespective of their nationality, size, or past transactions and finalize our choice in a fair manner by comprehensively evaluating their ability to offer superior quality, expertise, price, delivery, and other elements, as well as competitiveness, rationality, efforts for business security and other relevant matters.

- (2) Mutually Beneficial Transactions

- We share with our trade partners business challenges such as development and competitive pricing, set goals from a common perspective, and conduct joint efforts to achieve targets. We afford the highest priority to mutually beneficial transactions in terms of results thus obtained and make continuous efforts to strengthen trust as the basis of mutually beneficial relationships.

- (3) Environmental Responsibility

- In our corporate activities, we attach the greatest importance to global environmental preservation under all circumstances. Accordingly, we practice “green purchasing,” granting preference to environmentally responsible products, services, companies, etc.

- (4) Legal Compliance and Confidentiality

- We respect the principle of legal compliance and thoroughly observe relevant laws and regulations and generally accepted norms. We handle with the greatest care all kinds of information obtained from our customers and trade partners and make the utmost effort to prevent the loss or misuse of such information.

Other Major Initiatives for Supply Chain Management

Annual Conference with Major Business Partners

The TS TECH Group facilitates communication with business partners by providing opportunities to share information regarding purchasing strategies and policies. Holding an annual conference with major suppliers to explain our medium-term management plan and operating policies and to exchange information, we also present awards to business partners who have achieved excellent results in terms of cost, development, and quality as well as the ESG areas throughout the year.

At the annual conference, we showcase actual products and provide opportunities for delegates to gain firsthand experience of our technologies with the aim of deepening understanding of the company’s development policy. Through these initiatives, we will strengthen collaboration with our business partners while promoting the 15th Medium- Term Management Plan along our entire supply chain.

Supply Chain Risk Management

To address procurement risks, the TS TECH Group works to prevent all “events that impact production,” including natural disasters, fires, and financial challenges affecting its business partners. After gathering and displaying in visual form information in particular from upstream to downstream in the supply chain, we identify procured parts concentrated on a single supplier as “high-risk parts.” We then implement initiatives in cooperation with our business partners to prepare for contingencies such as natural disasters and secure alternative procurement sources. In the case of supply chains that are becoming more complex in terms of their distribution channels and hierarchy, we are aiming to minimize overall risk by reviewing their structures and working to consolidate and streamline them.

In response to the increasing frequency of natural disasters in recent years, we have also installed a disaster preparedness information system that combines supply chain information with hazard maps to present potential risks in visual form. We are working to speed up initial response and decision-making under our business continuity plan in the event of an emergency by automatically sending safety confirmation emails to business partners who are expected to be affected by the disaster.

Business Partner Assessments

To ensure a stable supply of high-quality products to our customers, the Group identifies as especially important those business partners that handle large-scale transactions or irreplaceable parts and conducts an assessment of them once a year. This is a comprehensive assessment that includes QCDDM* and ESG factors.

By prioritizing the selection of business partners with high overall capabilities based on the assessment results, we are also enhancing our Group’s competitiveness. Those business partners that are assessed as having scope for improvement are requested to draw up corrective action plans, and each department in the Group collaborates in implementing improvement initiatives, including on-site activities.

- Quality, Cost, Delivery, Development, and Management

Promoting Environmental Activities

CO2 emissions from Category 1 “Purchased goods and services” in Scope 3 account for 89.6%* of the CO2 emissions from the TS TECH Group’s business activities including the supply chain. We therefore recognize the importance of reducing emissions at our suppliers. Starting in April 2023, we have presented CO₂ emissions reduction targets not only to suppliers in Japan but also to suppliers worldwide, promoting reduced emissions across our entire supply chain. As part of these efforts, we ask that our business partners utilize energy conservation diagnoses by external organizations to incorporate specialized knowledge and increase effectiveness. Through objective analyses and operational proposals from expert perspectives, we have helped our business partners improve their energy efficiency and reduce CO2 emissions. Going forward, rather than simply making requests for reductions, we will continue to actively share best practices and work together with our business partners to reduce CO2 emissions throughout the supply chain.

- Percentage of total Group CO2 emissions in fiscal 2025

We also examine components to ensure they do not contain chemicals prohibited by laws and regulations in each country and region. We do not permit the use of chemicals prohibited by laws and regulations, even in manufacturing processes within supplier companies. Additionally, we have established rules to monitor the emissions of specified chemical substances designated by laws and regulations, and to report any issues that may arise to the relevant government.

Survey on Conflict Minerals

The TS TECH Group utilizes mineral resources, such as tin, tantalum, tungsten, and gold, to help create comfortable, safe, and attractive vehicle interior spaces. On the one hand, these are important materials that support the functionality and marketability of our products. On the other hand, they are also known as conflict minerals, and it has been pointed out internationally that they may be a source of funding for armed groups in the Democratic Republic of the Congo and surrounding areas.

Our Group's basic policy is not to use conflict minerals. In procurement, we continuously conduct country-of-origin surveys throughout the supply chain once a year to confirm that our products do not contain conflict minerals. In recent years, we have also expanded the scope of our surveys to include other mineral resources, including cobalt and mica, in striving to further reduce risk and ensure transparency.

Compliance with the Antimonopoly Act and Prohibition of Corruption

TS TECH has prepared and put into use its own Antimonopoly Act and Subcontract Act Compliance Manual, which sets forth the approach and considerations related to Japan’s Act on Prohibition of Private Monopolization and Maintenance of Fair Trade (“Antimonopoly Act”) and the Act against Delay in Payment of Subcontract Proceeds, etc., to Subcontractors (“Subcontract Act”). The relevant departments utilize the manual in day-to-day operations in conjunction with an accurate understanding of the two laws and a thorough, close examination into the legality of individual events.

TS TECH has created mechanisms that allow relevant departments to liaise with the department responsible for legal affairs and consult as needed with attorneys on events that cannot be definitively decided based solely on the manual. Moreover, TS TECH provides training on the Antimonopoly Act and the Subcontract Act in accordance with its rank-specific training programs to foster awareness of compliance among employees.

In March 2016, the Group issued new anti-corruption guidelines and anti-cartel guidelines as part of its continuing effort to build a solid framework for ensuring fair, honest business operations across all Group operations.In the rank-specific training programs that our employees attend, we also provide education relating to anti-corruption and anti-cartel issues, as stipulated under these guidelines.