Jan. 15, 2026

Introduction of new models

Experience Extraordinary Exhilaration with a Premium Interior - Honda Prelude -

Introduced by Honda Motor Co., Ltd. in September 2025, the new Prelude incorporates TS TECH seats and door trim.

We take a closer look at the development of products that create a comfortable, premium next-generation automotive cabin space

for the Prelude—a captivating car with a refined style and invigorating performance.

Profile

-

Hirooki Negishi

Large Project Leader (Seat)

Worked for more than 20 years in collision safety after joining TS TECH in 1998. Was transferred to the current department in 2022. He took on his first assignment as Large Project Leader, responsible for overseeing the entire development of new models, starting with the Prelude.

-

Koichi Mori

Large Project Leader (Seat)

After joining TS TECH in 1988, he worked in production at the Suzuka Plant for more than a decade before being posted to Brazil for eight years. After returning to Japan, he continued to be involved in production for new model development. He took on his first assignment as Large Project Leader with this project.

-

Haruki Mochizuki

Design Department 1

Design Project Leader (Seat)

Has worked in design ever since joining TS TECH in 2009. After working on both mass production models and advanced development, this was his first assignment as Project Leader (Seat) for a mass production model.

-

Takuya Hara

Design Department 1

Design Project Leader (Door)

Has worked on the design of door trims for various models since joining TS TECH in 2013. Served as Design Project Leader responsible for door trim design in this project as well.

-

Akira Ikezawa

Model Control Department

Seat Mass Production Verification

Has worked in seat prototyping ever since joining TS TECH in 2001. Worked on seat development for the NSX while being posted to North America from 2012. After returning to Japan, he has worked on the development of various sport-centric models.

Negishi The Prelude is a specialty coupe that combines the client’s (Honda’s) distinctive sportiness with comfort. The seats were required to have a holding performance to enjoy sporty driving, along with a special, enveloping seating comfort. Additionally, design was a high priority, as the client even asked us to consider the seats as an element of the vehicle’s exterior, not just the interior.

As a result, the key to development was how to realize a distinctive seat design appropriate for mass production while meeting the requirements for comfort, safety, and other aspects. In particular, achieving a compact and stylish design for the upper part of the backrest presented challenges in many areas.

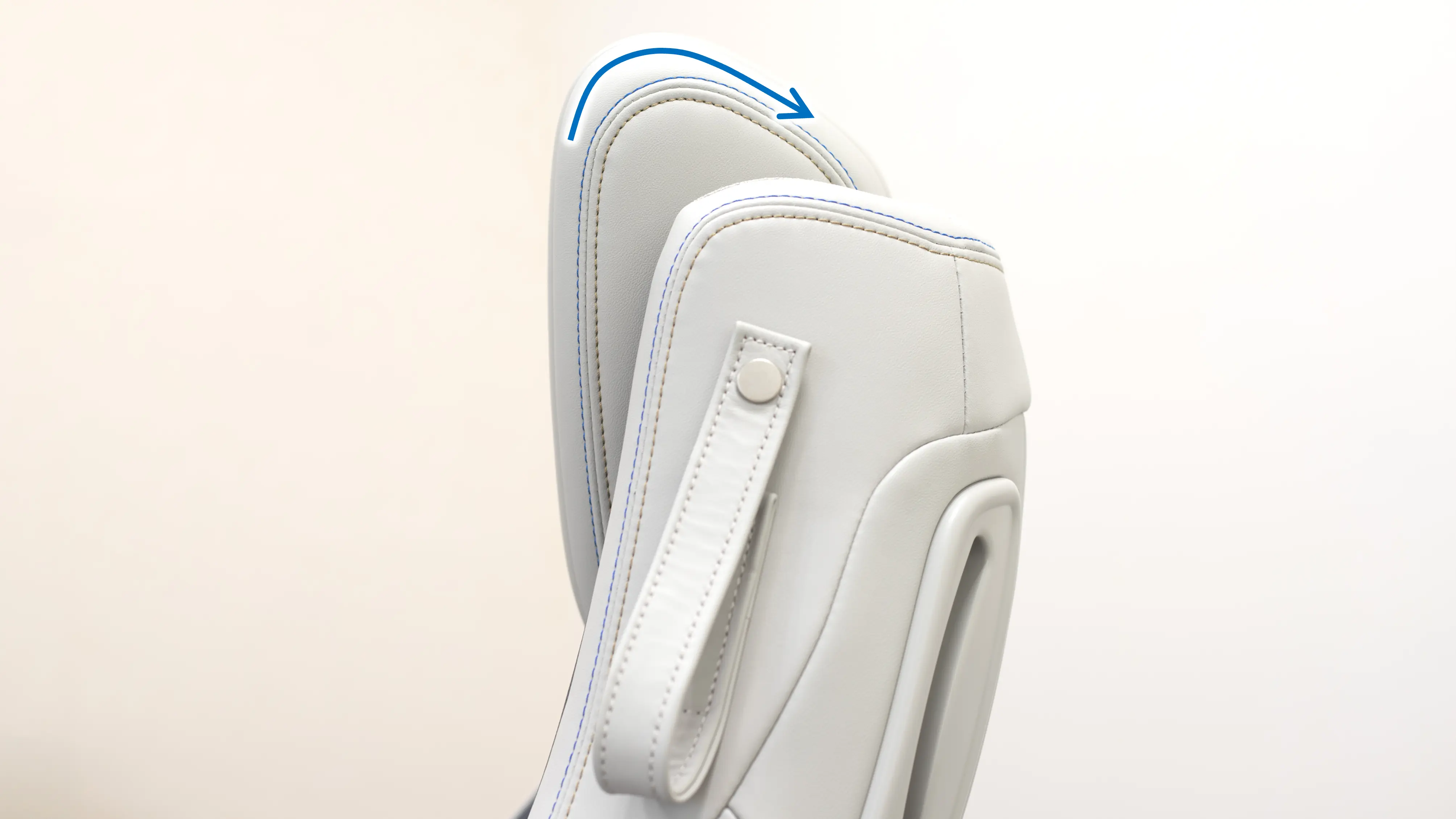

IkezawaThe most significant was the collar-like structure around the headrest, which involved really intense ideation to find a way to balance minimal assembly work with the required shape and strength. Ultimately, we devised a method of embedding a thick wire frame into the pad itself and forming the entire assembly as a single piece. (Fig 1) This resulted in a slim, high-backed seat with an imposing presence.

Another challenge was the headrest stitching. The curvature of the seam line, which was extremely sharp when viewed from the side, would meander as the seam allowance* was pulled when we tried to reproduce this line using conventional equipment. To overcome this, we achieved the distinctive shape of the headrest by adopting a new specialized sewing machine capable of cutting off the seam allowance while stitching. (Fig. 2)

* Extra margin of fabric added for sewing

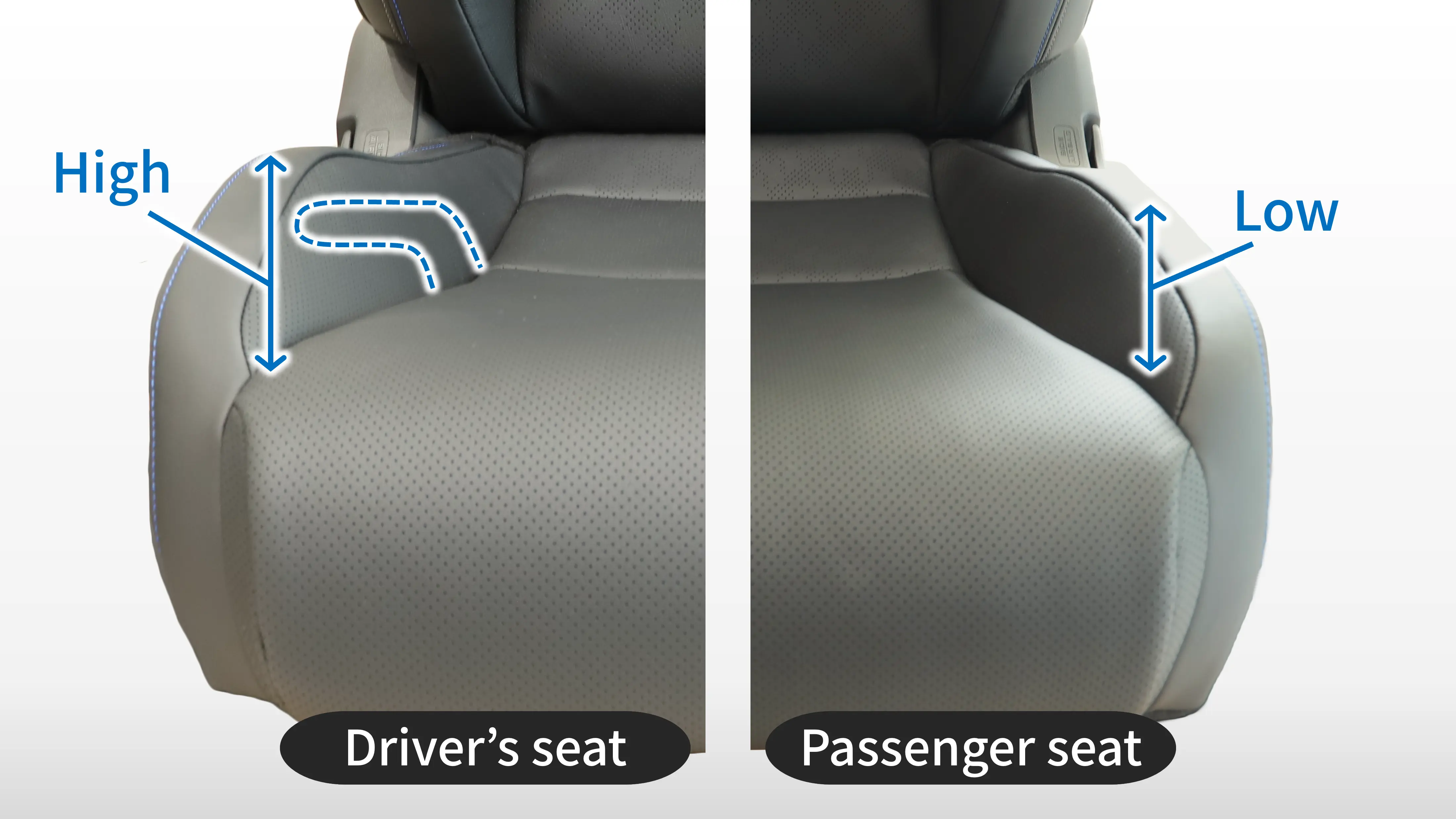

MochizukiBased on the vehicle concept of a comfortable ride for passengers and enjoyable sporty driving for the driver, the seat cushions for the driver and the front passenger were designed separately. Specifically, we used separate urethane hardnesses for each seat. Additionally, the side supports, or bolsters are higher and firmer for the driver’s seat to better hold the driver in place while cornering, but lower and softer in the front passenger seat for a relaxing ride and ease in getting in and out. (Fig. 3) We also added a layer of low-resilience urethane to both seats to create an enveloping feel such as that in a luxury sedan.

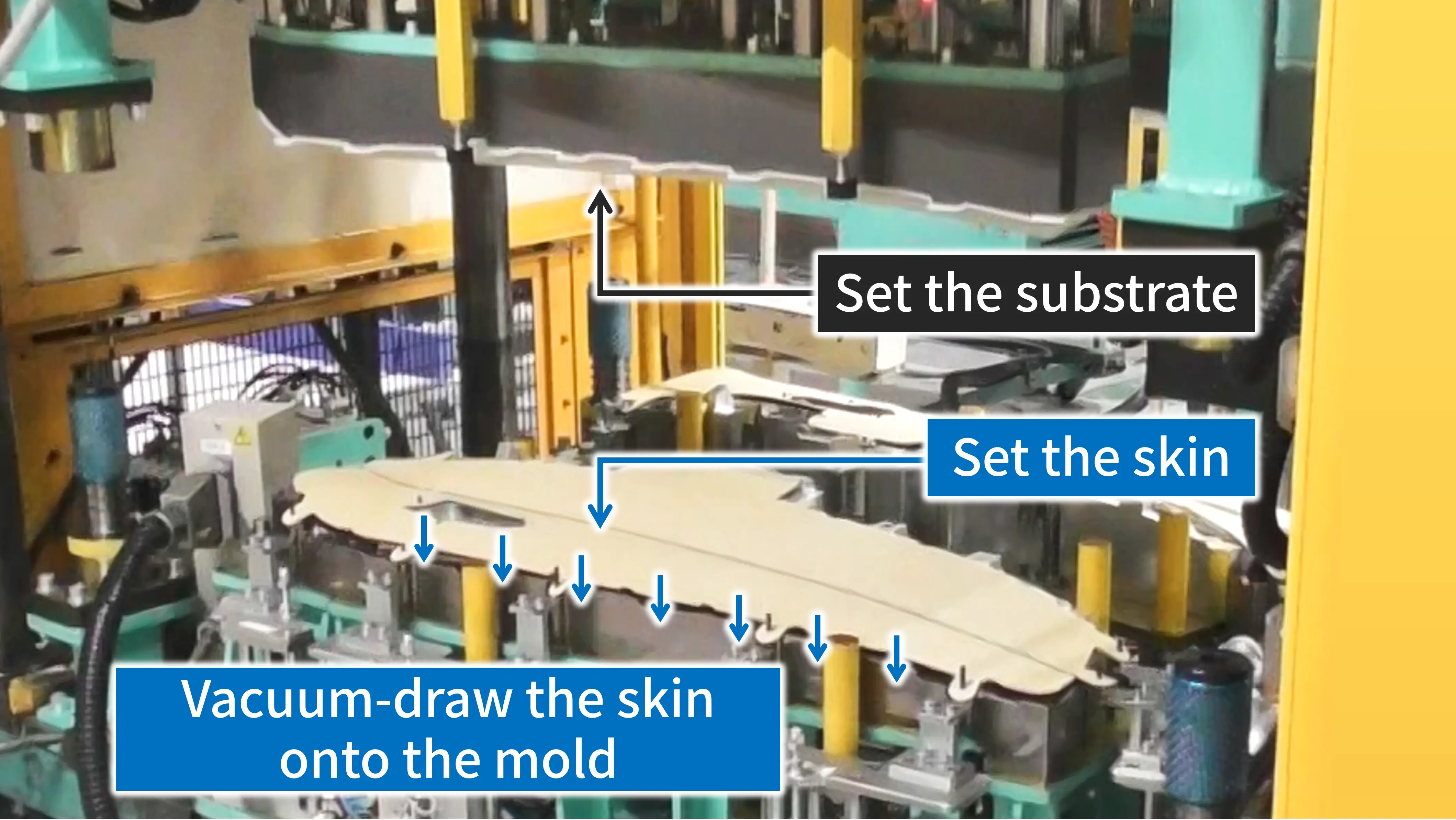

Mori As with the seats, a high-quality appearance was required for the door trim. Since the coupe’s doors are fairly large, the stitch lines naturally become long. If the stitch lines need to be straight, even the slightest distortion during skin bonding can significantly impair the appearance.

In response, we adopted a new method by which the skin is strongly vacuum-drawn onto the mold and held in place in a vacuum before being pressure-bonded onto the substrate* (Fig. 4). This enabled us to achieve a premium-quality appearance.

* Base parts for skin bonding

Hara Furthermore, since the door trim also acts as a brace for the driver’s knee during sporty driving, high rigidity is required across the entire panel. To achieve this, the design incorporates numerous reinforcing ribs in a grid-like pattern on the backside, as well as more fastening points to secure the part more firmly to the vehicle body.

On the other hand, simply pursuing rigidity could turn the door itself into a hazard in the event of a side collision. Therefore, we added a small crease in the armrest so that it would intentionally deform and absorb the impact of a side collision. (Fig. 5)

Negishi The Prelude’s seat frame is an integrated frame in use since the 2020 model. It has continued to mature through the development of numerous subsequent models. Building on that, this high-back version marks the culmination of our work. Working alongside veteran staff members, project team members, many of whom were young, worked through a process of trial and error to bring these distinctive seats to the world. It is our sincere hope that both drivers and passengers will enjoy to the fullest this premium next-generation automotive cabin space, including the doors, created through the teamwork of all project members.