Automobiles

Front seat

Comfortable, fatigue-resistant seats:

World-leading safety and light weight

To realize comfortable seats that support seated passengers, we pursue both comfort upon first sitting in the seat and resistance to fatigue after extended periods. Since comfort and fatigue resistance vary from individual to individual, we develop more comfortable seat products based on TS TECH’s proprietary concepts, which are grounded in repeated anthropometric studies, including quantitative evaluation of comfort and fatigue resistance sensations.

Safe, lightweight seat frames

These base frames achieve high neck impact resistance using our proprietary technologies. We've reduced weight dramatically while maintaining or improving strength and safety through the extensive use of ultra-high-tensile steel plates*1 and thin-plate joint technology.*2.

- Steel that provides higher strength than standard structural steel (which increases the challenge to achieve steel formability sufficient for thinner components).

- Technology for welding thin steel plates while ensuring strength

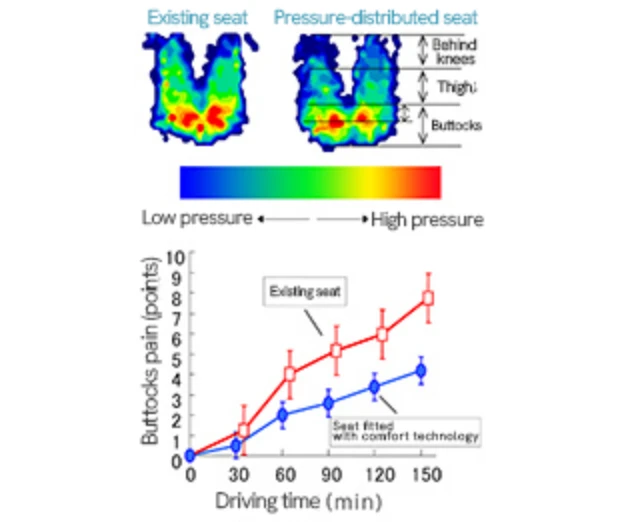

Seat pressure distribution technology

Pressure concentrated on a single point can cause pain over time and reduced blood flow to the lower body. We sought to develop seats resistant to fatigue even on long drives by distributing pressure on the buttocks through a combination of different forms, thickness, hardness, and surface material properties.

Mid seat

This realizes optimal comfort based on our understanding of comfortable posture.

Footrest structure

Used with an extended slide, this makes it possible to stretch the legs without worrying about the seat in front for a more relaxing posture.

Continuously adjustable armrest

This armrest is seamlessly adjustable to suit user preferences regardless of reclining angle.

Crease structure

This structure supports the head and shoulders at any reclining angle.

Rear seat

Seats that are easy to store under the floor

Enables a wide range of seating layouts

Simply pull the shoulder strap to fold the backrest forward and push the seat into the floor. Press slightly firmer to secure in place. That's all it takes to secure a flat, spacious luggage area. The seats can be stored separately on the left and right, making it easier to get in and out or load and unload through the hatchback.

-

Pull the shoulder strap to fold the backrest forward and push the seat into the floor. Then, just press slightly firmer to secure in place.

-

The seats can be stored separately on the left and right, making it easier to get in and out through the hatchback.

-

Store both seats to secure a flat luggage space.

Door trim

We offer quality products for elegant spaces at competitive prices.

Luxuriant leather grain, three-dimensional stitching, and other methods optimized for individual door trim parts result in products that create an elegant look.

Through the proactive use of automated production lines in processes such as production of armrests that do not use adhesives, we strive to achieve eco-friendly manufacturing while ensuring stable high quality.