Environmental Initiatives

Policy

In the interest of protecting the global environment, the TS TECH Group will work to reduce the environmental impact of all aspects of its corporate activities, especially the production of interior components for automobiles, and help create a sustainable society, aiming to be “A company sincerely appreciated by all,” which is one of the beliefs enshrined in the Group’s philosophy.

Environmental Action Plan

-

Compliance with Legal and Other Requirements

Strive to prevent environmental pollution and protect biodiversity and ecosystems primarily through compliance with requirements, such as environmental laws and regulations and environmental standards, and proper chemical management. -

Reduction of Environmental Impact

Aim to mitigate the impacts of climate change and realize a sustainable recycling-based society by striving to save energy and resources through collaboration across the supply chain, based on life cycle assessments that cover all stages in the product life cycle, from development through sourcing, production, logistics, marketing, disposal, and reuse. -

Continuous Improvement of Environmental Management

Endeavor to continuously improve environmental and energy performance by setting environmental targets based on environmental and energy management systems, and regularly reviewing them. Provide the information and management resources needed for such improvement and also work toward the utilization of products and equipment that will improve energy efficiency.

October 2018, Resolution of the Board of Directors (Revised)

Initiatives to Strengthen Environmental Management

The Group is promoting environmental management system ISO 14001 certification at all of its facilities around the world. We are united in our efforts to continuously reduce the burden on the environment. Seeking additional measures to efficiently reduce CO2 emissions, TS TECH adopted the ISO 50001 energy management system at all of its sites in Japan in fiscal 2019 and obtained certification. Going forward, we will continue with efforts to bolster our environmental and energy management not only to reduce the burden on the environment but also to decrease costs by using resources more efficiently.

Acquisition of ISO 14001 Certification

| Area | Location |

|---|---|

| Japan | TS TECH CO., LTD. |

| KYUSYU T・S CO., LTD. | |

| SUN CHEMICAL INDUSTRY CO., LTD. | |

| Americas | TS TECH AMERICAS, INC. |

| TS TECH USA CORPORATION | |

| TS TRIM INDUSTRIES INC. | |

| TRI-CON INDUSTRIES, LTD. | |

| TS TECH ALABAMA, LLC. | |

| TS TECH CANADA INC. | |

| TRIMONT MFG. INC. | |

| TS TECH INDIANA, LLC | |

| INDUSTRIAS TRI-CON DE MEXICO, S.A. DE C.V. | |

| TST MANUFACTURING DE MEXICO, S. DE R.L. DE C.V. | |

| TS TECH DO BRASIL LTDA. | |

| China | GUANGZHOU TS AUTOMOTIVE INTERIOR SYSTEMS CO., LTD. |

| GUANGZHOU TECH INTERIOR TRIM MANUFACTURING CO., LTD. | |

| GUANGZHOU TSK AUTO PARTS CO., LTD. | |

| NINGBO TS AUTOMOTIVE INTERIOR INC. | |

| WUHAN TS-GSK AUTO PARTS CO., LTD. | |

| Asia and Europe | TS TECH TRIM PHILIPPINES, INC. |

| PT. TS TECH INDONESIA | |

| TS TECH (THAILAND) CO., LTD. | |

| TS TECH (KABINBURI) CO., LTD. | |

| TS TECH SUN INDIA PRIVATE LIMITED | |

| TS TECH SUN RAJASTHAN PRIVATE LIMITED | |

| TS TECH (MANDAL)PRIVATE LIMITED | |

| TS TECH Hungary Kft. |

- Out of 38 consolidated subsidiaries, 26 have obtained ISO 14001 certification.

Acquisition of ISO 50001 Certification

| Area | Location |

|---|---|

| Japan | TS TECH CO., LTD. |

| Asia and Europe | TS TECH SUN RAJASTHAN PRIVATE LIMITED |

- Out of 38 consolidated subsidiaries, two have obtained ISO 50001 certification.

Internal Environmental Audits

TS TECH has established an environmental and energy audit program that consists of annual audits of each site. The audits take into account the environmental and energy impact of the sites and the results of past audits. These internal audits examine measures to reduce environmental impact and energy consumption, the effect of these measures, compliance with related laws and regulations, and the status of the administration of ISO international standards, among other items. We promote swift, proper correction of deficiencies and non-compliance items detected in audits, aiming to improve our environmental management.

Compliance with Environment-Related Laws and Regulations

Under our environmental and energy management systems, TS TECH has prepared a list of legal and other requirements at each site and reviews the laws and requirements that we must comply with at the beginning of each fiscal year. We also evaluate the status of compliance every six months. Over the period from fiscal 2020 to fiscal 2023, there were no violations of environmental laws and regulations.

Compliance with environmental laws and regulations (non-consolidated)

| FY2020 | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|

| Environmental violations (cases) | 0 | 0 | 0 | 0 |

| Environmental fines (yen) | 0 | 0 | 0 | 0 |

Environmental and Energy Management Education

TS TECH provides employees with various educational programs related to environmental and energy management under its ISO management system. Under the ISO 14001 standard, we conduct environmental education with the objectives of reducing environmental impact and preventing pollution. Under ISO 50001, in addition to offering energy conservation training tailored to each production facility provided by the Energy Conservation Center, Japan, we have also introduced our own energy-saving diagnostics focused on improving equipment operation.

Since 2022, we have been acquiring knowledge on effective energy-saving techniques with the benefit of expert insight and input. We have focused on energy conservation using inverters for motors and equipment, seeking to strengthen the development of human resources specialized in this area. We have been rolling this knowledge out horizontally across the entire Group, including sites outside Japan.

To catalyze even more effective measures, these specialists not only learn the basics of energy management but also delve deeply into specific management methods for particular facilities. Going forward, we will continue to develop human resources who can take the lead in promoting energy conservation at each of our sites, Meanwhile, we will keep providing general education, as well, seeking to improve employees’ environmental awareness and skills.

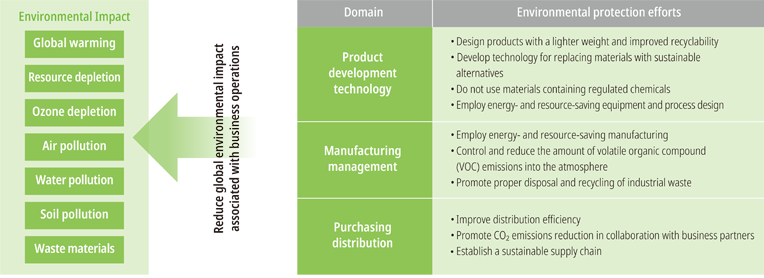

Environmental Impact of Business Activities and Environmental Initiatives

TS TECH identifies and strives to reduce the environmental impact of its business activities in each region of the globe.

Development-Focused Measures

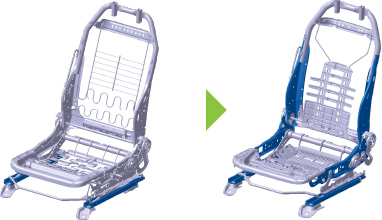

We understand that reducing the weight of our products is one of the most effective ways in which we can reduce our impact on the environment. For example, our seat frames account for a large portion of the weight of our products, so we strive to apply a variety of weight-reducing technologies wherever possible, while further improving safety and comfort in line with evolving needs. The seat frame installed in the 2020 Honda Fit is about 28% lighter than our previous core frame. We accomplished this by using more ultra-high tensile strength steel and thin-plate welding technology. It is now being used in many automobile models worldwide.

In addition to weight-reducing technologies, we are focusing on reducing CO2 contained in our products through technologies utilizing cellulose nanofiber (CNF) and other plant-derived biomass materials. Compared to conventional door trims made from petroleum-derived materials, we have succeeded in reducing the amount of CO2 contained in these products by 60% by using plant-derived biomass materials (for resin/synthetic leather coverings), and we are continuing our research with the goal of applying this technology to mass-produced products.

Looking ahead to the future shift to EVs, we are also pursuing technology development that contributes to carbon neutrality from various perspectives, including developing seat heaters that efficiently heat at low power to help increase electric mileage (cruising range) and climate-control seats that help reduce electricity consumption.

Production-Focused Measures

Under the policy of “Evolving toward sustainable manufacturing and building a globally efficient production system,” our Manufacturing Division works hard to ensure our manufacturing is both competitive and environmentally friendly. The main initiatives include accelerating automation of production lines and reducing electricity usage by standardizing energysaving technologies, introducing next-generation energy-saving technologies, and utilizing regenerative energy*1.

An example of electricity reduction utilizes karakuri*2 means to achieve work automation without consuming energy. In November 2022, we exhibited a karakuri mechanism that uses equipment exhaust air, at the Karakuri Kaizen Exhibition hosted by the Japan Institute of Plant Maintenance, winning the silver award in the parts feeder contest category. We are currently working to further reduce environmental impact by developing equipment that utilizes regenerative energy, such as a method of generating electricity from a karakuri mechanism.

- Converting surplus energy generated from equipment into electricity for reuse

- Karakuri refers to equipment or mechanisms that improve processes with minimal energy or cost through the use of gravity, gears, the principle of leverage, etc.

Installing Environmentally Friendly Equipment

Installing environmentally friendly equipment Initiatives to reduce CO2 emissions include installing environmentally friendly equipment such as solar power generation systems and rainwater reuse systems when replacing buildings at each site, which helps to reduce CO2 emissions and groundwater usage. We are also actively working to reduce logistics losses by taking steps such as realigning production with consolidated external warehouse functions. In fiscal 2023, we newly installed solar power systems at the Hamamatsu Plant and Suzuka Plant, and expanded the system at the Saitama Plant.

At the expanded facilities of TS TECH INDIANA, LLC, we installed a solar power system with storage capabilities in June 2022. By combining this solar power generation with green power certificates, we have reduced CO2 emissions from electricity to zero. In these ways, we are accelerating efforts around the world to reduce our environmental impact.