Our Strengths Built over Time

- Titles shown were current as of the publication of the “TS TECH Integrated Report 2025” (November. 2025).

Solid Corporate Foundation

Over many years, the TS TECH Group has established a solid base of technological capabilities for creating safe, secure, comfortable, and appealing products through manufacturing excellence. We have also built a global product supply system capable of responding quickly to environmental changes and market diversification. In addition, as “A company dedicated to realizing people’s potential,” which is one of our vision statements, we have fostered a corporate culture of respect for the individuality and abilities of each employee, thereby encouraging continuous growth and the embrace of challenges. As the source of our corporate competitiveness, this corporate culture contributes directly to innovating technology and improving quality.

Our corporate foundation is built on our proven technological capabilities, global supply system, and a corporate culture deeply rooted in our corporate vision statement of being “A company dedicated to realizing people’s potential.” Leveraging this strong corporate foundation, we will continue to take on the challenges involved in realizing infinite possibilities, creating new value and achieving sustainable growth.

History of Our Strengths

| 1950s | Seat division of Teito Fuhaku Kogyo Corporation (TS TECH predecessor) begins production of Honda motorcycle seats |

|---|---|

| 1960s | After launching manufacture of automotive seats for Honda at Asaka Plant (current headquarters location), seat division of Teito Fuhaku Kogyo spins off to form Tokyo Seat Co., Ltd. Focusing on developing new customers, production of seats for Suzuki and Yamaha Motor automobiles and motorcycles begins at Hamakita Plant (now Hamamatsu Plant) |

| 1970s | After establishing multiple domestic subsidiaries, Tokyo Seat accelerates business expansion by establishing a subsidiary in North America, marking first Group overseas venture |

| 1980s | Non-consolidated number of employees surpasses 1,000; development capabilities reinforced with introduction of 2D CAD, 3D measuring devices, and body pressure measurement system |

| 1990s | New R&D facility established in Tochigi region; development function strengthened on all fronts, including design, prototyping, mold manufacturing, and safety evaluation Foundation for regional segment-based business operations laid with expansion into Asia, China, and Europe |

| 2000s | Consolidated number of employees surpasses 10,000; global competitiveness activities strengthened, including incomparable quality initiatives and business structure reform lines |

| 2010s | Policy of building a foundation for ESG management adopted in the 13th Medium-Term Management Plan; ESG management initiatives strengthened across environmental, social, and governance areas |

| 2020s | Cross-industry collaborations leveraged and software development capabilities enhanced to accelerate value creation through total automotive cabin coordination |

Secrets behind TS TECH Strengths

Unrelenting pursuit of manufacturing excellence and solid financial foundation built over years

The relentless pursuit of manufacturing excellence embedded in the TS TECH Philosophy is the source of our strong corporate foundation. In addition to pursuing safety, comfort, product appeal, and quality, our philosophy calls on each employee to approach their work with a sincere and creative attitude. Permeating every aspect of our products, this spirit lies behind our numerous products, earning high praise from our customers around the world and serving as the source of the TS TECH Group’s competitiveness.

Another major strength of the Group is the solid financial foundation that we have established over many years. Our stable profit structure and strategic capital policy enable us to maintain a flexible framework capable of responding to economic fluctuations and market uncertainties. This financial foundation enables us to make long-term capital investment and R&D, driving our continuous pursuit of many challenges.

Reinforcing Our Strengths

Enhancing competitiveness through strategic resource allocation

By strategically allocating resources, we are working to boost competitiveness in order to achieve sustainable corporate value growth. We are particularly focused on allocating limited management resources with precision to key areas for corporate growth, including reorganizing subsidiaries in Japan, constructing a new Production Technology Building on the Saitama Plant premises, and introducing initiatives such as an employee stock incentive program. This precise allocation of resources aims to boost the competitiveness of our businesses and build an even firmer foundation for the future.

With these initiatives, we will reinforce both quality and quantity of our six forms of capital—most notably, manufactured, intellectual, and human—to further bolster corporate sustainability and growth.

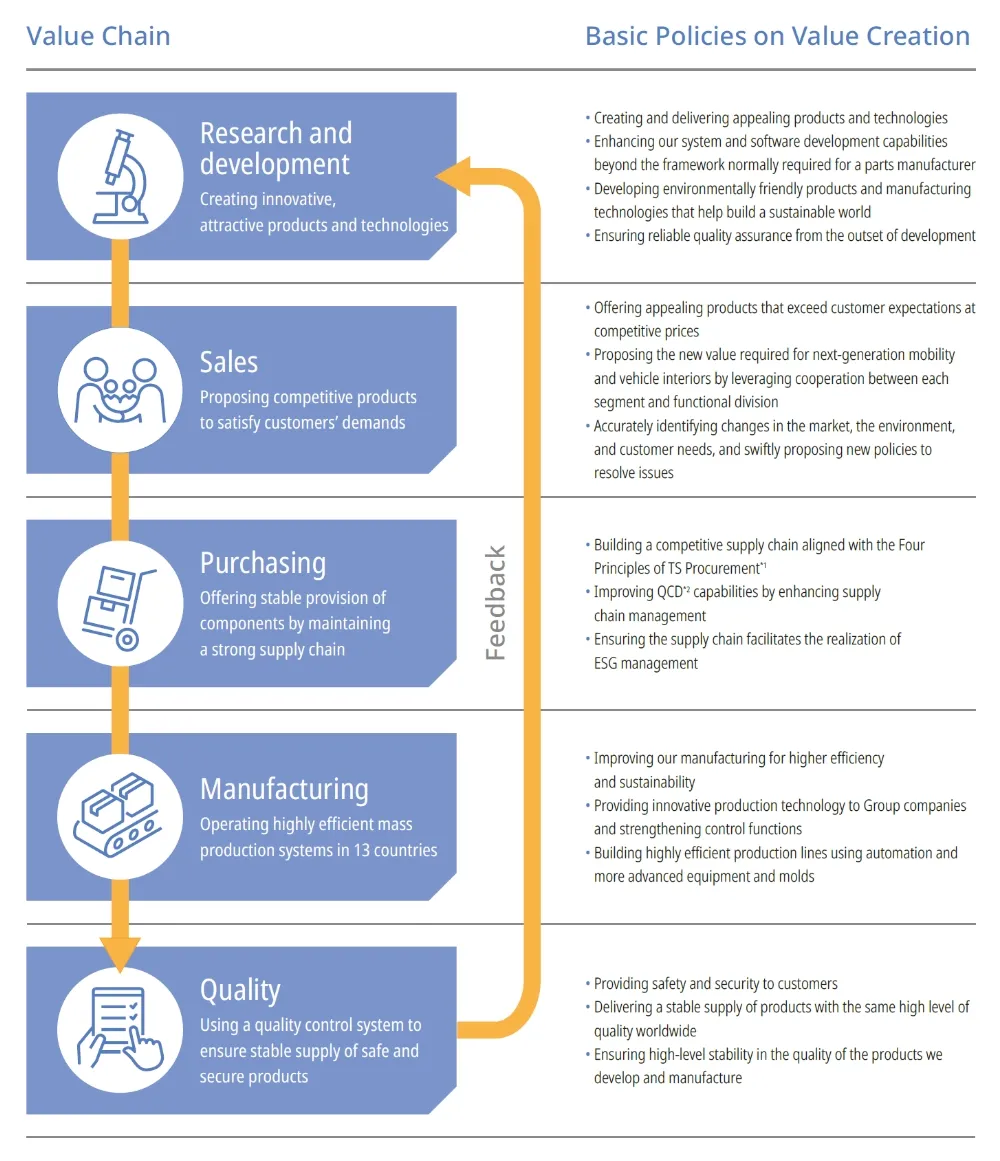

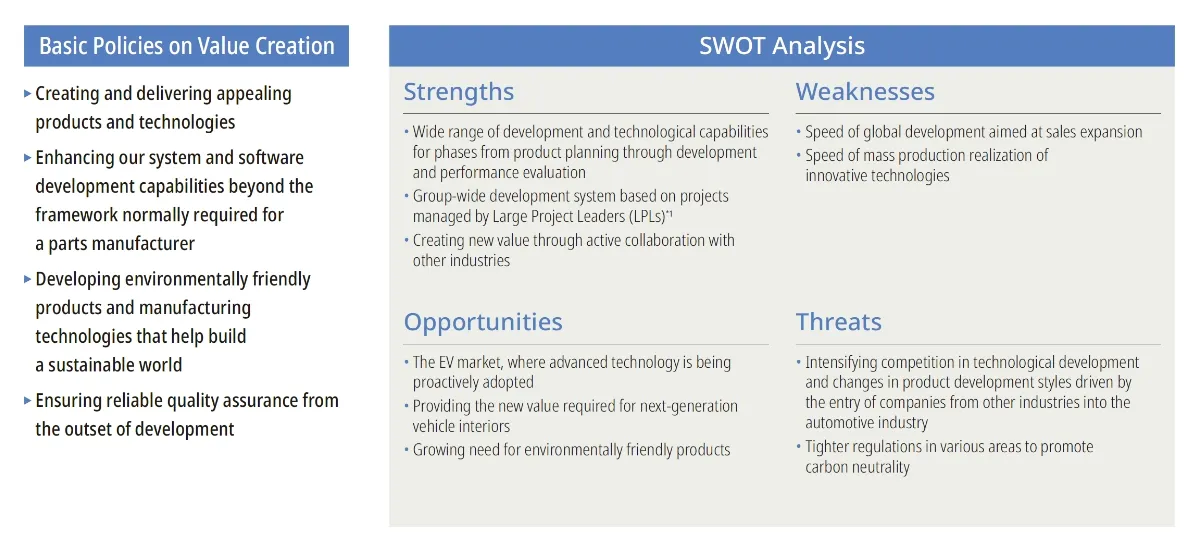

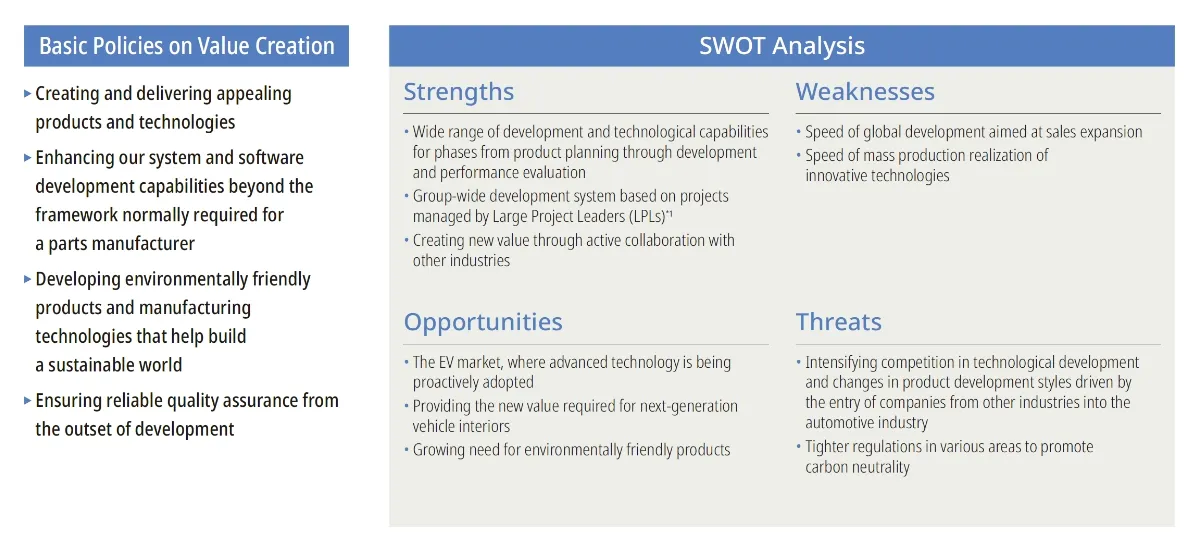

Research and Development

The TS TECH Group is determined to achieve its materiality goals and 2030 targets in order to further enhance corporate value. To do so, we will develop advanced technologies leveraging our strengths: safety, the environment, and the creation of attractive products. We will accomplish this by vigorously pursuing the development of new value in the domain of next-generation vehicle interiors. Using a rapid decision-making structure, we are enhancing various initiatives to promptly deliver competitive products to customers by identifying and responding to social changes and needs.

As “A company dedicated to realizing people’s potential,” which is one of our vision statements, we will develop the next generation of engineers and generate new innovations based on diverse ideas, as we move to realize sustainable growth by developing groundbreaking technologies.

Value Creation

- Creating and delivering appealing products and technologies

- Developing system software that goes beyond those of a typical parts manufacturer

- Developing environmentally friendly products and manufacturing technologies to help build a sustainable world

- Ensuring reliable quality assurance from the outset of development

Representative Director, Senior Managing Officer, Corporate Development and Engineering Division Executive General Manager

History of Our Strengths

| 1990s | Focused on development to reduce environmental impact and accelerated initiatives on product weight reduction technologies |

|---|---|

| 2000s | Strengthened the foundation and framework for collision safety evaluation and technology development by introducing a dynamic sled testing facility |

| 2010s | Enhanced development of electrical device technologies such as seat heaters and air conditioning to enhance product appeal and comfort Achieved the No. 1 ranking in Japan for comprehensive patent strength in seat technology among all automotive manufacturers and suppliers (still No. 1 today) |

| 2020s | Creating appealing products and technologies for the entire vehicle interior; strengthening systems and software development capabilities with the aim of further enhancing product appeal Focusing on cultivating advanced engineers and developing electronic control units (ECUs) Strengthening environmental technology development capabilities; promoting the development of environmentally friendly steel materials, product application technologies, and proprietary products that contribute to recycling |

Secrets behind TS TECH Strengths

New technologies and creation of new value underpin competitive superiority

To maintain our competitive edge, we have consistently conducted thorough benchmark surveys to set targets for the weight and quantity of individual component parts, driving forward technology development in seat frames and comfort-focused features. As a result, our lightweight, high-rigidity seat frames and products, which offer both comfort and safety, have gained market recognition. Meanwhile, this has helped to foster highly skilled engineering talent.

In recent years, we have focused on solving user challenges and creating new value in vehicle interiors, working closely with our customers to devise unique products exclusive to TS TECH. For example, we are actively promoting vibration control technology that can alert drivers to danger, air conditioning control technology, and the use of electric furnace steel and recycled resins that help to reduce environmental impact. In all these efforts, we seek to help build a sustainable mobility society and enhance corporate value.

Reinforcing Our Strengths

Creating comfortable interiors for the era of autonomous driving

As autonomous driving technology advances, automotive usage is diversifying, ushering in an era where software creates new value. The TS TECH Group is adapting to these changing times by striving to provide innovative interior products, starting with seats that are optimal and comfortable for each individual user. Building on core seat frame technologies and the elemental technologies supporting comfort and safety that we have developed over the course of many years, we are working to establish a framework capable of proposing functional devices as systems that adapt to the ways in which people spend time in vehicle interiors in accordance with automotive evolution, and to bring these to market quickly.

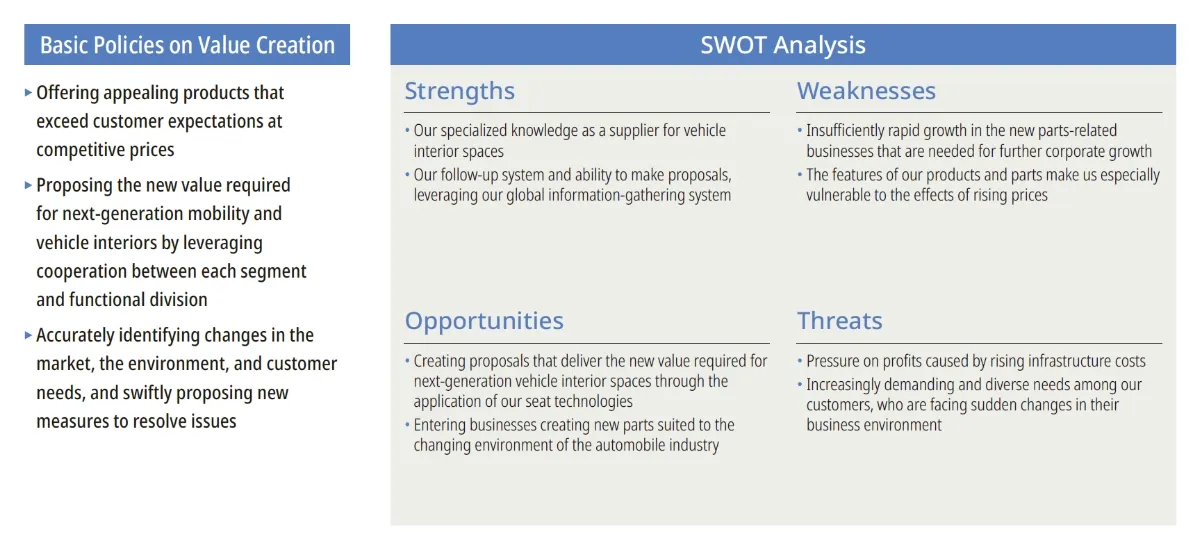

Sales (Honda Group)

The business we do with Honda Motor Co., Ltd. and the Honda Group (its network of associated companies), our main customers, is an important foundation. We aim to raise our share to at least 70% of all the automobile seats sold to the Honda Group by 2030, thereby ensuring the further growth of our business.

The automobile industry is undergoing a major transformation due to the shift to EVs and the advance of autonomous driving technology. Amid these changes, the Group is leveraging its global network of 45 companies in 13 countries worldwide and rapidly proposing and bringing new products to market. These new products look ahead to the diversifying needs of each region, and in such, they will further enhance customer satisfaction.

Value Creation

- Offering appealing products that exceed customer expectations at competitive prices

- Proposing the new value required for next-generation mobility and vehicle interiors by leveraging cooperation between each segment and functional division

- Accurately identifying changes in markets, environments, and customer needs, and swiftly proposing new measures to resolve issues

Director, Managing Officer, Corporate Sales and Purchasing Division Executive General Manager

History of Our Strengths

| 1950s | TS TECH’s sewing technology was first recognized through the production of Honda’s work uniforms, which led to the start of the motorcycle seat business |

|---|---|

| 1960s | With Honda’s entry into automobile manufacturing, TS TECH began domestic production of automobile seats and door trims, establishing the foundation for our current business structure |

| 1980s | Established an automobile interior products manufacturing plant in Ohio, USA, and commenced overseas local production of products for Honda |

| 1990s | Began sales activities in the Asian region with the establishment of TS TECH (THAILAND) CO., LTD., which would become a key production base in the region |

| 2000s | Commenced regional management through TS TECH NORTH AMERICA, INC. (now TS TECH AMERICAS, INC.) and strengthened sales functions in the Americas Established GUANGZHOU TS AUTOMOTIVE INTERIOR SYSTEMS CO., LTD. and strengthened production and sales functions in the China region Through these initiatives, we established local sales frameworks in various regions around the world. |

Secrets behind TS TECH Strengths

Strong partnerships built up over many years

The TS TECH Group began doing business with Honda, our current principal customer, during the era of our predecessor, Teito Fuhaku Kogyo Corporation. Since then, we have established sales bases not only in Japan but further afield in the Americas, Asia, and China. As Honda’s business has expanded, we have grown alongside it by building a strong and trusted partnership with Honda as our key customer. By maintaining sales bases in each region, not only have we responded swiftly to customer needs but we have also won more market share in each region by focusing on key models and offering optimal proposals in response to changes in the business environment. Amid ongoing environmental changes, we aim to further evolve our strong partnerships with Honda into a solid foundation for business growth and manufacturing excellence. By accurately responding to shifting conditions and addressing region-specific challenges, we will continue to deliver proposals that exceed customer expectations.

Reinforcing Our Strengths

Enhancing sales functions for business reforms

The value demanded of automotive interior products is undergoing a transformation, driven by advances in autonomous driving technology and heightened environmental awareness, including the promotion of carbon neutrality. The TS TECH Group views this transformation as an opportunity and will actively propose high-value-added products that enable more comfortable experiences in vehicle interiors. What is more, we will promote sustainable business practices in consideration of the environment by pursuing product development that takes into account the entire product life cycle, including not only manufacturing but also disassembly and reuse. To execute these initiatives more rapidly and reliably, we will analyze what resources are lacking within the TS TECH Group from various perspectives, while actively considering the selection of new partners and the utilization of external resources.

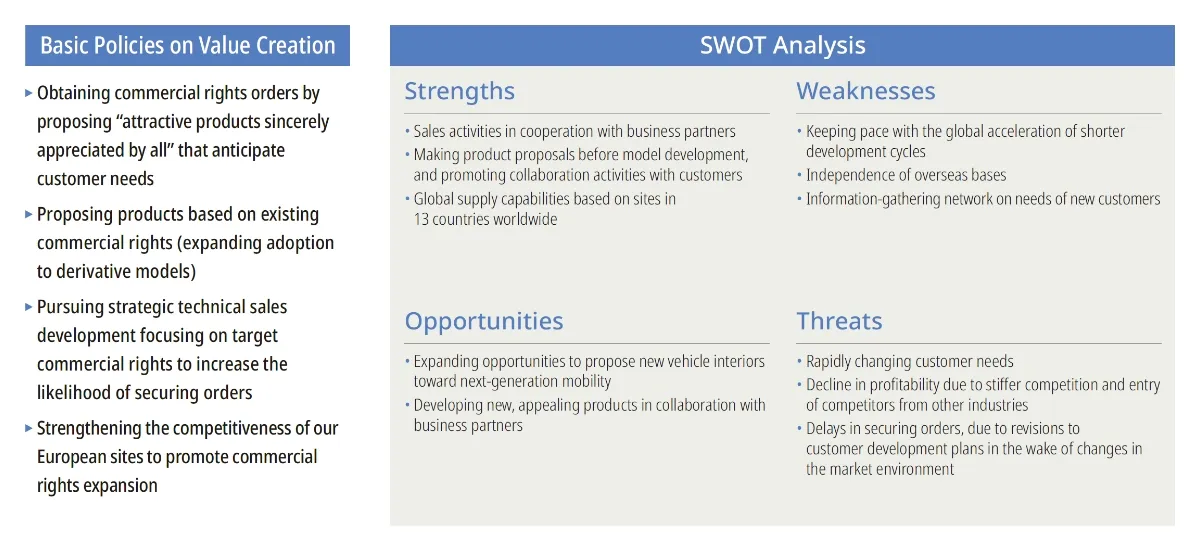

Sales (New Businesses)

The business environment surrounding the TS TECH Group is undergoing rapid change, particularly in the Chinese market. To achieve steady, ongoing business growth, it is essential that we expand our acquisition of commercial rights in the “new businesses” domain, which encompasses business with customers beyond the Honda Group.

As we strive to achieve our target of ensuring that new business sales account for 30% of our consolidated revenue by 2030, we will constantly anticipate future trends in the automobile industry and engage in strategic sales activities. To this end, we will aim to expand our new businesses by securing optimal resources in coordination with each regional headquarters, while providing “attractive products sincerely appreciated by all” that capture the needs of customers all over the world.

Value Creation

- Obtaining commercial rights orders by proposing “attractive products sincerely appreciated by all”

- Ongoing sales activities based on existing commercial rights

- Expanding commercial rights through tie-ups with local business partners in China

- Strengthening order acquisition activities with a focus on the Suzuki Group through our Indian joint venture company

Operating Officer, New Business Management Division Executive General Manager

History of Our Strengths

| 1960s | Established Hamakita Plant (now Hamamatsu Plant); commenced business with Suzuki and Yamaha Motor, laying the foundation for the solid relationships that continue to the present |

|---|---|

| 1970s | Established TRI-CON INDUSTRIES, LTD., for local production of motorcycle seats for Kawasaki in North America, for our first overseas expansion |

| 2010s | Opened a new sales base in Germany; acquired commercial rights for the Volkswagen Group through proactive sales activities Opened a new development and sales base in Detroit; acquired new commercial rights through proactive sales activities with U.S. automakers |

| 2020s | Established the New Business Management Division with the aim of conducting flexible and agile sales activities in coordination with overseas bases Established joint venture companies in China and India, strengthening sales activities targeting local automobile manufacturers |

Secrets behind TS TECH Strengths

Strategic technical sales using a global framework

Driven by proactive overseas expansion, the TS TECH Group has grown to become a global enterprise with bases in 13 countries. Each base operates autonomously, establishing optimal supply chains and highly efficient production systems for each location. Leveraging these regional foundations, through information gathering and analysis via marketing in coordination with each base, we identify commercial rights to target, and propose products that align with customer needs by drawing on the technological capabilities we have cultivated over the years. As a result, we have accumulated a track record of orders, including regionally optimized power seat frames for Asia and detachable rear seats for the European market. We will continue to deploy technical sales activities that fully demonstrate the strengths of each base in order to fulfill our Mission Statement: “We shall provide comfortable, high-quality products at competitive prices to our customers worldwide.”

Reinforcing Our Strengths

Enhancing technical sales activities through tie-ups with business partners

To conduct sales activities with even greater precision in order to acquire new commercial rights at each of our bases, we are proactively advancing collaborations with business partners with detailed knowledge of regional circumstances. In 2025, aiming to expand our business in India, where the automotive market is on a growth trajectory, we established the joint venture company KRISHNA TS TECH AUTO PRIVATE LIMITED with the Krishna Group, a major seat supplier to Maruti Suzuki. By sharing the technologies and extensive experience the two companies have amassed, we are building a product development structure that will generate further added value. We are vigorously deploying order acquisition efforts targeting new customers and new commercial rights acquisitions among automobile manufacturers and others in India.

Purchasing

As the business environment surrounding our Group and the value demanded of automobiles undergo rapid transformation, the continuous evolution of our supply chain is critical to further growing corporate value. Moreover, to remain “A company sincerely appreciated by all” whose presence is valued by all our stakeholders, it is also important to strengthen ESG management initiatives across the entire supply chain.

In the purchasing domain, we will build a robust, sustainable supply chain while further strengthening partnerships with our suppliers, based on the three axes of “supply chain restructuring for enhanced competitiveness,” “initiatives for prediction and prevention to ensure stable supply,” and “CO₂ emissions reductions.”

Value Creation

- Building a competitive supply chain aligned with the Four Principles of TS Procurement※1

- Improving QCD※2 capabilities by enhancing supply chain management

- Building supply chains toward the realization of ESG management

Director, Managing Officer, Corporate Sales and Purchasing Division Executive General Manager

- The principles TS TECH has established to ensure fair and just transactions and to construct and maintain win–win relationships with our suppliers globally

- Quality, Cost, and Delivery

History of Our Strengths

| 1990s | Began purchsing activities in the Asian region with the establishment of TS TECH (THAILAND) CO., LTD., which would go on to become a key production base in the region In Japan, consolidated the purchasing functions that had been located at each individual domestic plant, establishing a centralized purchasing system; laid the foundation for a resilient supply chain |

|---|---|

| 2000s | Commenced regional management through TS TECH NORTH AMERICA, INC. (now TS TECH AMERICAS, INC.) and strengthened purchasing functions in the Americas Established GUANGZHOU TS AUTOMOTIVE INTERIOR SYSTEMS CO., LTD. and strengthened purchasing functions in the China region Through these initiatives, we established local purchasing frameworks in various regions around the world. |

| 2010s | Building on the foundation of our solid local purchasing system expertise, enhanced global competitiveness by newly assigning cost management functions to each region |

| 2020s | Established the Corporate Sales and Purchasing Division through integration with the Corporate Sales Division to strengthen purchasing management functions and maximize added value |

Secrets behind TS TECH Strengths

Building a supply chain capable of adapting to environmental changes

The cost structure of automobiles is undergoing a major transformation in line with the shift to next-generation vehicles, including the expansion of the EV market and advances in autonomous driving technology, with customer needs becoming more sophisticated than ever before. Moreover, the impact on procurement costs from recent rises in energy prices and labor costs has been substantial, requiring the construction of a supply chain capable of flexibly responding to such external environmental changes. Even under these circumstances, we are constantly optimizing our supply chain by streamlining complex commercial channels, implementing initiatives to reduce production losses caused by procured parts, and expanding the onboarding of competitive new parts manufacturers. Furthermore, through benchmarking and close dialogue with our customers, we are working to establish a framework that enables us to address fundamental challenges more effectively, supported by efforts to foster a culture of continuous improvement among our employees.

Reinforcing Our Strengths

Enhancing partnerships with business partners

Collaboration with business partners dealing with everything from steel to resin materials, and the strong relationships we maintain with them, are strengths for the Group. We will continue to work to further strengthen these partnerships in order to forge a competitive, sustainable supply chain. In addition to our existing co-creation activities starting from the early stages of development, we are working diligently to eliminate losses and ameliorate issues attributable to us, in order to further create competitiveness and expand mutual benefits. We are also working together with our business partners to improve not only their production sites but also their corporate structure. Through these activities, we will build a supply chain trusted by all our stakeholders together with our business partners, and leverage it for future growth.

Manufacturing

Strengthening our corporate structure through further development of our manufacturing—the core business of the Group—will be essential for achieving our 2030 Vision. To this end, we are developing a high-efficiency production structure that can consistently leverage our competitive edge over rival firms, in order to establish a solid foundation for supporting the growth of our business.

We are advancing sustainable manufacturing globally under the guiding concept of integrating design and production. Our efforts focus on three key pillars: promoting automation of production lines in manufacturing, strengthening organizational capabilities through the horizontal deployment of best practices in management, and building a sustainable production structure through ongoing energy-saving initiatives in the environmental domain.

Value Creation

- Developing high-efficiency, sustainable manufacturing

- Providing innovative production technologies to Group companies and strengthening oversight capabilities

- Building highly efficient production lines using automation and more advanced equipment and molds

Managing Officer, Corporate Manufacturing Division Executive General Manager

History of Our Strengths

| 1960s | The Suzuka Plant, Gyoda Plant (now Saitama Plant), and Hamakita Plant (now Hamamatsu Plant), are established; mass production of products for use in motorcycles and four-wheeled vehicles commences |

|---|---|

| 1990s | The Engineering Center is established in Tochigi Prefecture, to provide integrated support for all processes from R&D to mass production, and to resolve technological challenges occurring in production Our mold production capabilities for both development and mass production are significantly enhanced. In particular, the establishment of in-house mold manufacturing technologies makes a major contribution to improving product quality and shortening lead times |

| 2000s | The introduction of jig lines, in which seats are fixed to jigs before being assembled, improves production efficiency while also ensuring quality is delivered “Business structure reform lines” operate with automated component conveyance and an automated shipping system that enables TS TECH to maintain its own unique production framework, independent of fluctuations in customers’ production schedules |

| 2010s | A manufacturer of press-formed molds is brought into the Group as a subsidiary, with steps taken to ensure higher efficiency and quality levels in the manufacture of seat frame components A highly automated jig-conveyor production line for door components is developed in-house and operates at full scale. The line contributes to cost reduction and the internalization of core manufacturing technologies |

| 2020s | Seat frame welding process starts on fully automated production lines in which all processes can be completed by robots As part of our global mother plant functions, seat assembly and verification lines are established at the Saitama Plant to accelerate the early stabilization and refinement of manufacturing processes |

Secrets behind TS TECH Strengths

Pursuing rigorously high-efficiency, high-quality manufacturing

To achieve high-quality and cost-competitive manufacturing, the Group has established an integrated in-house system covering everything from the development of molds and automation equipment to production. This structure enables high-cycle molding of resin components, optimized yield in press-formed parts, and labor-saving operations through the use of robotics. In addition to introducing digital technologies into production facilities, we are enhancing productivity and operational strength by developing equipment that reflects on-site feedback and by sharing and deploying improvement initiatives across the Group. To pursue high-efficiency and high-quality manufacturing, we have centralized production technology development within our Engineering Center, which oversees prototype and mass production line design. This structure enables us to quickly feed back production-related challenges—closely linked to quality, cost, and delivery (QCD)—into product specifications.

Reinforcing Our Strengths

Strengthening our initiatives for optimizing production through the establishment of a new Production Technology Building

We are establishing a new Production Technology Building on the premises of the Saitama Plant to accelerate efforts to advance manufacturing technologies and optimize our production systems in collaboration with the Engineering Center. The facility will serve as a central hub for next-generation manufacturing, equipped with pilot lines that enable early verification and integration of product specifications.

Through this facility, we are also promoting the deployment of digital and new manufacturing technologies across all production sites, including those overseas. At the same time, we are accelerating the in-house development of production equipment and strengthening our ability to tailor facility specifications and optimize production systems to meet the specific needs of each site—ultimately enhancing our overall profitability.

Quality

Among the many components used in vehicles, the Group’s products are among those positioned closest to passengers and play a vital role in ensuring their safety. For this reason, we recognize that without delivering reliable quality that guarantees safety, we cannot earn the trust of our customers—nor can we enhance our corporate value.

To achieve sustainable corporate growth, we are leveraging our accumulated expertise while promoting digital transformation to deliver next-level quality assurance through predictive detection and the reduction of human error. In addition, we are working closely with our business partners to raise quality awareness across the entire supply chain and to ensure consistently high standards, aiming to remain “A company sincerely appreciated by all.”

Value Creation

- Providing safety and security to all customers

- Delivering a stable supply of products with the same high level of quality worldwide

- Ensuring consistently high quality in the products we develop and manufacture

- Enhancing our quality assurance systems through digital transformation

Operating Officer, Corporate Quality Assurance Division Executive General Manager

History of Our Strengths

| 1980s | As part of efforts to strengthen our corporate foundation, the Quality Division is leading company-wide quality improvement initiatives that engage all employees Reexamination of raw materials and production processes is contributing to enhanced product competitiveness |

|---|---|

| 1990s | The Group is expanding its “TC Circle” quality control activities globally. The TC Circle World Tournament functions as a forum for summarizing and sharing best practices across the organization The TC Circle program—our Group-wide, bottom-up initiative to improve quality and streamline operations—has been sustained to this day |

| 2000s | The concept of a “Good Quality Company,” set forth in the Group’s long-term vision, lays the foundation for a corporate culture that prioritizes quality above all else, with the aim of achieving world-class standards Quality improvement initiatives are being implemented across all manufacturing sites under the theme of “Incomparable Quality.” These efforts include proactive investment in equipment and fostering a stronger awareness of defect prevention |

| 2020年代 | Quality improvement efforts are being accelerated through quality improvement meetings with business partners, enhanced quality awareness initiatives, and the introduction of camera-based inspection systems into manufacturing processes |

Secrets behind TS TECH Strengths

Quality assurance structure further enhanced through close partnership between production sites and the Corporate Quality Assurance Division

For a company committed to quality-focused manufacturing, quality defects represent a serious risk that can lead to a loss of customer trust. Behind every defect lie not only dozens of minor issues but also hundreds of near-miss incidents. Recognizing this, we have built a structure that enables proactive defect prevention by raising quality awareness across the Group. This effort is driven by four key pillars: global quality assurance training, enhanced responsiveness to problems and issues, misconduct prevention, and quality awareness initiatives.

To further strengthen our quality framework, we have appointed quality assurance officers at each production site to ensure consistent global standards. In addition, the Corporate Quality Assurance Division in Japan provides strong support for quality improvement activities at all locations.

Reinforcing Our Strengths

Quality control that does not depend on humans

While machine-based inspection processes are increasingly being adopted, certain tasks—such as operational checks and pass/fail evaluations—still rely on human inspectors. As a result, the risk of quality defects due to human oversight or judgment errors remains. To eliminate these risks, we are advancing digital transformation by systematically converting our accumulated expertise into data. This enables the development of systems capable of detecting early signs of abnormalities and identifying subtle changes that may go unnoticed by the human eye. Through these efforts, the Group is building a proprietary quality assurance framework that minimizes dependence on human judgment, ensuring both high efficiency and consistently high product quality.