Development structure

Primary development flow

-

STEP 01

Research and advance planning

We undertake market research and other activities to clarify our product position within the market, and formulate competitive proposals based on the research results.

-

STEP 02

Planning and proposal

We propose plans that reflect the results of our own research and studies based on concepts proposed by automakers.

-

STEP 03

Design

We apply CAD to generate proprietary designs. Design data is continually refined to reflect the views of individual sections.

-

STEP 04

CAE analysis

We apply CAE to further improve designs by analyzing and evaluating product processing methods, structures, and materials before prototyping.

-

STEP 05

Prototype research

We produce prototypes after comprehensive efforts to improve precision through CAE analysis. These prototypes are used to finalize specifications for improved production efficiency and product performance.

-

STEP 06

Impact testing

We use dynamic impact testing equipment to obtain precision testing results and verify product safety.

-

STEP 07

Durability and performance testing

We implement a wide range of testing to ensure the strength and durability of products and assess impacts on durability and performance under various scenarios.

-

STEP 08

Review

Product design specifications are repeatedly reviewed from multiple perspectives. The issues identified are reported to related sections, and resulting improvements are subjected to an approval process.

LPL structure for unique and highly competitive product development

TS TECH has adopted an LPL (large project leader) structure in its development of new models. LPLs are assigned to coordinate individual sections, including overseas facilities, through comprehensive management ranging from planning and proposals through mass production. The LPL serves as a liaison with the customer to help guide individual sections in developing unique and highly competitive products.

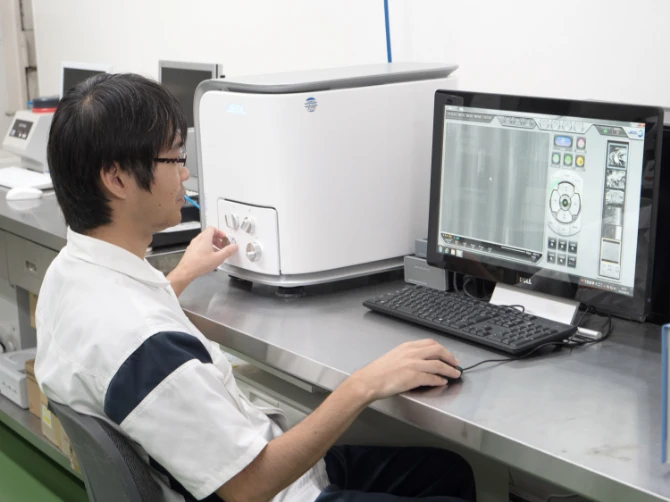

Thorough materials evaluations

TS TECH evaluates materials to produce even higher quality products. We select the best materials by evaluating all of the materials that make up a product, including fabric, resin, urethane, steel, and adhesives. We ensure thorough quality by evaluating not just the products, but their materials.

Advanced electrical device development handled entirely in house, from feature proposals through system verification

Today’s increasingly advanced automotive seats contain numerous electrical devices, which perform various roles as key parts that make seats more valuable in terms of safety and comfort. We handle technological developments, from proposals for new seat features through control configuration and system verification, in house.

Refining product specifications through advanced prototype testing technologies

Certain issues such as assembly challenges and visual defects may be detected in the process of actually building a product, despite designs suggesting no apparent issues. We verify product precision, finish, and any issues encountered in mass production through CAE analysis procedures and prototypes fabricated by highly skilled engineers based on completed plans.

Product specifications are refined through improvements by providing feedback on such issues to individual sections.

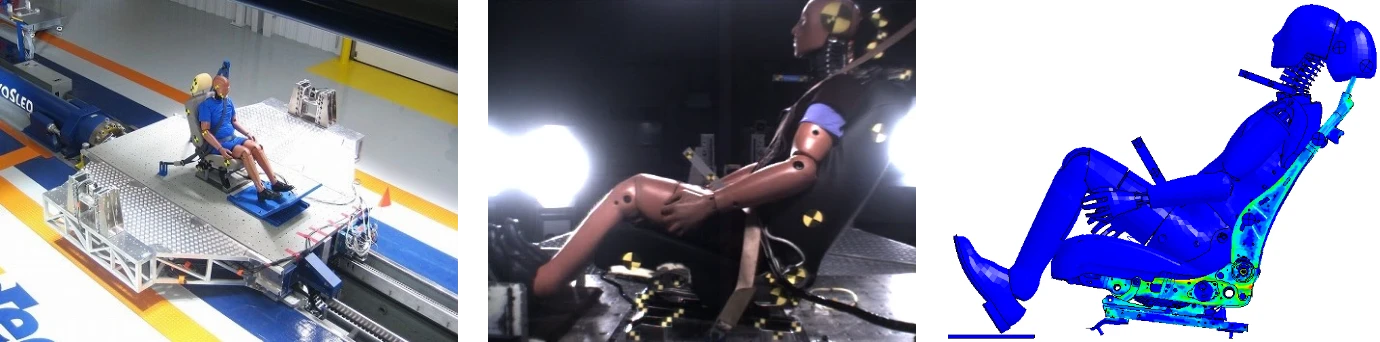

Testing seat safety using precision impact testing equipment

Our Safety Technical Center in Tochigi Prefecture, Japan, and TS TECH AMERICAS in North America operate three dynamic testing systems for developing products with high safety performance, accumulating data from numerous tests of impact safety performance from various perspectives. In addition to enabling high-precision testing and assessment, the test data collected is used for CAE analysis.